Drain pump with internal float switch. Submersible drainage pumps with internal, integrated float.

The possibilities of drainage pumps are different, but their designs are quite similar. Most pumps have the ability to independently turn on and off, which depends on the minimum and maximum water levels.

Submersible domestic pumps are often equipped with a float switch that monitors the water level in the tank during pumping. If the emptying reaches a certain point, the float automatically turns off the device, giving it a kind of signal - tilt down.

It is important to monitor the free movement of the float. Connecting and disconnecting the float comes from the mains. The built-in float switch is often used to operate drainage and fecal pumps, controlling the pumping of water from the pits, but even in the case of filling tanks without it is difficult to do.

Rains, breakthroughs of sewer pipes and their clogging often cause flooding of the premises. And here, depending on how much solid impurities are in the water, pumps with float switches (drainage or fecal) come to the rescue.

Such pumps are usually installed on the floor, on the flat bottom of the tank or reservoir, and the possibility of special suspension by the handle is also possible.

TOP-8 best models

Drainage pumps are powerful and durable, and they are reliable and safe to use.

Today, the domestic market can offer the consumer such a huge number of options for brands and models that just run their eyes.

But here is a list of the best, in our opinion, options:

The popular and versatile Pedrollo TOP

Excellent pump, specially designed for automatic operation. This apparatus is preferably used for pumping water without admixture of solid particles.

Excellent pump, specially designed for automatic operation. This apparatus is preferably used for pumping water without admixture of solid particles.

The unit is easy to operate, has a good level of power and great for eliminating water from small rooms, pools, tanks and bathtubs, as well as to supply water to fountains and summer cottages.

Features of this model:

- equipped with corrosion protection, withstands shock and mechanical damage

- the base of the pump is made in the form of a durable polymer lattice, which protects the device from unnecessary large particles

- withstands long-term loads and can work non-stop;

- in case of overheating, an emergency shutdown system comes into operation;

Specifications:

- Power - 370 W

- Head - 8 m

- Delivery -13.2 m3 / h

- Manufacturer: Pedrollo

- Country of Origin: Italy

- Average price: 7-8 thousand rubles

Inexpensive pump Gileks "Drainage tank"

A popular drainage pump with a built-in float, the main purpose of which is to pump clean and ground water, as well as pumping fecal particles.

A popular drainage pump with a built-in float, the main purpose of which is to pump clean and ground water, as well as pumping fecal particles.

Often, Dzhileks used in irrigation works, for which the pump delivers water from sources or wells. Some variations of the pump are made of plastic and serve exclusively for clean water.

Features:

- the package includes a waterproof cable 10 m long;

- it works even in the case of a non-full immersion in the liquid, which is due to the cooling of the electric motor using the built-in heat exchange chamber

Specifications:

- Power - 200 W

- Head - 7 m

- Delivery - 9 m3 / h

- Maximum fluid temperature - 40 ° C

- Manufacturer: Gileks

- Country of manufacture: Russia

- Average price: 3 thousand rubles

Grundfos Unilift - time-tested classic

It is used to pump contaminated water from rooms, pools, tanks, as well as to reduce the amount of groundwater. This pump can be either portable or stationary.

It is used to pump contaminated water from rooms, pools, tanks, as well as to reduce the amount of groundwater. This pump can be either portable or stationary.

Features:

- made of stainless steel;

- equipped with thermal protection;

- various immersion and location of the pump (vertically, horizontally, at an angle);

Specifications:

- Power - 400 W

- Head - 10 m

- Delivery - 14 m3 / h

- Maximum fluid temperature - 55 ° C

- Manufacturer: Grundfos

- Country of Origin: Hungary

- Average price: 13 thousand rubles

Universal pump GNOME

A popular model that is used for pumping groundwater containing clay and gravel from pits and pits.

A popular model that is used for pumping groundwater containing clay and gravel from pits and pits.

An indispensable assistant in irrigation, private and industrial construction, in the maintenance of mines and basements.

Features of this model:

- possesses a durable cast-iron housing, which makes it possible to use GNOM in any conditions;

- the filter is easy to remove and clean;

- characterized by long duration without overheating;

Specifications:

- Power - 1.5 kW

- Head - 10-16 m

- Delivery - 10-16 m3 / h

- Maximum fluid temperature - 35 ° C

- Manufacturer: Polesielectromash plant

- Country of manufacture: Ukraine

- Average price: 5 thousand rubles

Expensive but reliable - Grundfos KP

![]() Household float pump for dirty waterwhose coating is corrosion resistant. The device is used for pumping wastewater in domestic conditions, as well as pumping water from rivers and other bodies of water to gardens.

Household float pump for dirty waterwhose coating is corrosion resistant. The device is used for pumping wastewater in domestic conditions, as well as pumping water from rivers and other bodies of water to gardens.

Features of the pump:

- the device is equipped with thermal protection;

- can be installed in narrow, inaccessible places;

- no need for maintenance;

Specifications:

- Power - 0.3 kW

- Head - 9 m

- Delivery - 14 m3 / h

- Maximum fluid temperature - 50 ° C

- Manufacturer: Grundfos

- Country of Origin: Hungary

- Average price: 13 thousand rubles

Economy option: Ergus Drenagio 400 F

Submersible model designed specifically for pumping g  room water and characterized by low noise during operation.

room water and characterized by low noise during operation.

Features:

- the case is made of plastic with a high level of strength;

- excellent indicators of duration and productivity;

Specifications:

- Power - 400 W

- Head - 5 m

- Delivery - 7.5 m3 / h

- Maximum fluid temperature -35 ° C

- Manufacturer: Ergus

- Country of Origin: Italy

- Average price: 1,5 thousand rubles

Herz WRS 40 / 11-180

Submersible Fecal Pump Automatically Pumping Out

stock water with feces from rooms and ponds. The device easily grinds the fibers that it encounters during the pumping of contaminated water.

Features:

- wRS series pumps are very economical

- pumps waste water over long distances due to high pressure

Specifications:

- Power - 1500 W

- Head - 23 m

- Delivery - 330 l / min

- Maximum fluid temperature - 40 ° C

- Manufacturer: HERZ

- Country of Origin: China

- Average price: 14 thousand rubles

Karcher SDP 5000

Submersible pump with an internal float for pumping contaminated water in automatic mode. Works with dirt particles up to 20 mm long.

Submersible pump with an internal float for pumping contaminated water in automatic mode. Works with dirt particles up to 20 mm long.

Features:

- equipped with an ergonomic handle for comfortable movement;

- characterized by powerful parameters of productivity, pressure and water supply;

Specifications:

- Power - 250 W

- Head - 5 m

- Delivery - 5000 l / h

- Maximum fluid temperature - 35 ° C

- Manufacturer: Karcher

- Country of Origin: Germany

- Average price: 2.5 thousand rubles

Now you are familiar with the best brands of pumps for drainage and pumping dirty water and you can confidently choose the right machine!

If you still have questions, ask them in the comments to this article. We will also welcome any feedback and feedback.

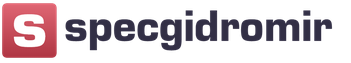

Without a float, the owner of a private house or suburban area will probably not even try to list. This device becomes indispensable when draining basements, pumping water from trenches under the foundation, or from the pool, when cleaning it. It can be used to organize a watering system from a well or other source, to drain the area from flood or groundwater, and in many other cases.

Features of the use of drainage pumps with a float integrated in the switch

The variety of types and models of drainage pumps is quite large, but floating-type devices are popular because of the high degree of reliability and unpretentiousness during operation. They do not have problems characteristic of installations with remote float switches, connected in some cases with incorrect control of the water level, because of which the devices can simply overheat and fail.

Especially effective is their use in small pits when pumping water from pools, boats and other containers with a low water level. As a result, the float mechanism is simply fixed on the surface of the water, while the apparatus continues to work, despite the fact that the water level is critically low and does not provide the necessary degree of cooling of the pump.

Key Benefits of Unipump SUB 257 Pumps

The use of a submersible pump with an external float switch is not possible in narrow pits, since it requires space for the float to run, which is excluded at these facilities. But if in such cases a drainage pump with automatic switching on without a float is used, that is, a device in which the float is already integrated in the housing, there are no problems during operation. The only condition for this is that the size of the sump or other tank from which water is to be pumped out should be slightly larger (wider) so that the pump can technically be installed.

Given the design features of such installations, nothing interferes with the built-in float, and, therefore, it will be able to perform its function and turn off the pump when the water level becomes critical. This principle of operation is used both in installations submersible typeand semi-submersible. For example, it is used in drainage pumps from the Russian manufacturer Unipump.

The model of the SUB 257 P series is characterized by a rather high productivity of up to 6 m 3 / hour, especially when used in conditions of pumping clean or low-polluted waters from narrow pits. At the same time, the power of the device is low, for example, for the model SUB 257 P - 250 W, but it is quite enough to perform the functions assigned to the pump. Another important parameter of the pump, namely the water pressure, produces 6 m of water column at the outlet, which is a completely optimal indicator for devices used for domestic purposes.

When choosing this type of floatless pump for summer cottage, it should be taken into account that it is not recommended to use them for pumping highly contaminated media. Sometimes, the fact that their operation in automatic mode does not allow to completely dry the sump or other container is called a drawback. In this case, the solution is simple - manual control with blocking the operation of the built-in float, but care should be taken to prevent overheating of the engine.

Scope of drainage pumps without float Unipump SUB

Our company “Alfatep” offers a wide selection of drainage pumps, among which the Unipump SUB series models, which are distinguished by an affordable price and performance that fully meets the requirements of owners of cottages and country houses, draw particular attention to consumers. Reliability of the pump is guaranteed by a robust sealed housing, for the manufacture of which a composite material is used - technopolymer.

The main functions for which you should buy a drain pump SUB 257 P or another model of this series from Unipump:

- pumping and discharging wastewater and flood waters from the site;

- drainage of yachts and boats, containers, pools, wells, basements;

- recommended for pumping clean water or effluent with a small inclusion of solid particles, the size of which does not exceed 5 mm;

- can be used for transportation of soap drains whose temperature does not exceed 35 ° C;

- organization of irrigation on the site;

- forced circulation of water in the system, but subject to short-term operation.

The advantage of this series can be considered the possibility of operation under the condition of full or partial immersion, which allows to reduce the minimum level of pumped water to only 10 mm, but only when working in manual mode, for automatic such a limitation is 50 mm. The maximum depth for installation is an immersion level of 8 meters. Float switchbuilt into the pump housing allows the device to be operated in two modes: automatic and manual.

All these characteristics are relevant for Unipump SUB 257 P, \u200b\u200bas well as other models of this series, which require connection to a conventional power supply network (220-230V). The device’s package also includes a cable of sufficient valley, equal to 10 m, which allows convenient use of the device for pumping water to almost anywhere in a summer cottage or a private house.

The drainage pump without float for giving from the Alfatep company

In the online store of the Alfatep company, you can select and purchase a drainage pump, while the price of popular models is very attractive to our customers. We are always ready to provide advisory assistance in choosing the installation model that best meets the needs of the consumer and operating conditions. All questions of interest can be asked by phone or, more conveniently and efficiently, right on the site, using the feedback service.

On the website of the online store you can quickly place an order for the purchase of your favorite pump model, and our transport service will deliver to the object as soon as possible.

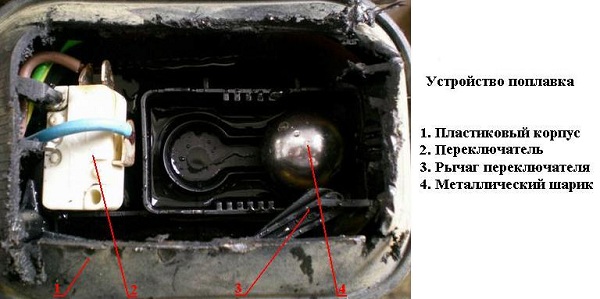

A float switch for electric pumps is an element of the overall system of the pumping station and controls the water level in the tank. They are also the most important protection against dry running of the pump with a float, which will increase the operational life of the device.

Switches help reduce clogging due to sand entering the system. They perform several necessary functions, and in some pumping stations several floats are used at once.

1 Description of float switch

Submersible and drainage pumps operate in environments where fluid may suddenly run out or become contaminated. In this case, further pumping water already mixed with a lot of dirt can seriously harm the system. Therefore, a float switch for pumps is essential to prevent breakage due to dry running. Some floats need to be installed independently, while other pumps are manufactured with an internal float.

They are located in a variety of tanks - from tanks in wastewater pumping systems to drinking water wells. And the tasks that floats perform, depending on the place of use, may vary. Also in one tank there is the opportunity to put more than one float, each of them performs different tasks:

- monitoring the operation of the main pump;

- monitoring the operation of the additional (auxiliary) pump, as well as improving its effectiveness;

- level sensor;

- overflow sensor.

A level sensor is required to submersible pump did not work on dry run and thus did not suck heavily contaminated water, which leads to breakdown of the entire station. Overflow sensor is required so that the water tank does not overflow. Depending on the type of container, this can lead to serious problems, up to a short circuit.

1.1 Varieties of floats for pumps

Float switches are connected to various types of pumps and can also be integrated. To install a separately purchased float on the pump does not require much effort and extensive knowledge. A pump with an integrated float is much simpler, albeit more expensive, if you need to provide the system with float control as quickly as possible.

There is a lightweight drainage pump with a built-in float switch and a heavy one. The first type is suitable for a pump with a float used in water supply - wells, wells. And also in drainage systems. Second drainage pumps with an integrated float, heavy, suggest, firstly, a polluted environment, and secondly, difficult operating conditions. A drainage pump with a float of the second type is used in drains: sewer, rainwater, drainage.

You should start your choice of a water level sensor with the definition of goals - for water supply of a dacha, farm, house, watering a plot, an easy one is better. For the organization of a sewer system, drainage or sewage, it is recommended to purchase a heavy unit.

1.2 Technical characteristics of the float switch

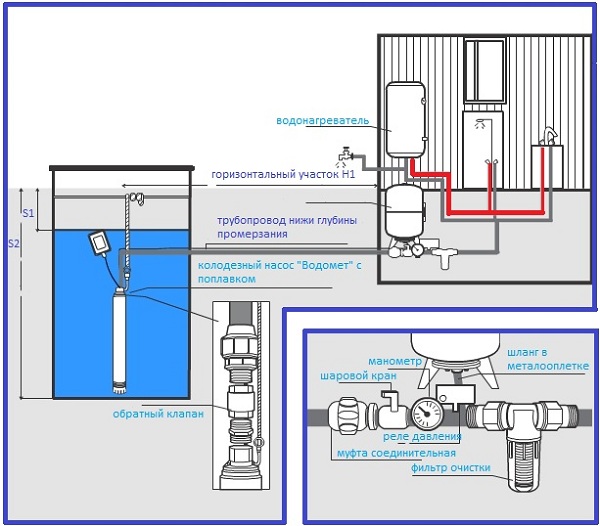

The body of the device is made of plastic materials of various shapes. It requires absolute tightness and waterproofness. A float consists of the following elements:

- floating plastic housing;

- electric switch;

- lever for switch contacts;

- steel ball;

- three wires in the cable.

The wires are connected: one to the closed contact, the other to the open, the third is common. There are floats with two wires. They break the electrical circuit if you want to turn off the submersible pump and connect the circuit if you want to turn it on again. Three-wire switches are universal, they are suitable for tracking not only dry run, but also overflow. There is one common and two wires, between which the modes are switched.

Their wires vary in color. Common, as a rule, is a black wire. The blue wire turns off the system when the pump for pumping starts to “run aground” and there is too little water in the tank (for example, in the well). The brown wiring adjusts the pump when the tank is full.

The float changes its position because there is air inside. Accordingly, when it is under water, then try to emerge. When there is little water left, it sinks. For adjustment use a special load.

Depending on the length of the wire from the load to the float, the values \u200b\u200bat which the pump turns on or off will change. Thus, they are easily adjusted manually to prevent overflow or dry running. It is worth considering that the float should turn off the operation while the pump is still under water with a small margin.

A steel ball adjusts the position of the lever depending on the position of the float itself. The lever, in turn, switches the contacts to enable or disable the pump with a float. Magnets are used to fix the ball in the required positions. The slope at which the ball moves from one position to another, most often is 70 degrees, but should be clarified when buying a device.

Characteristics of the float switch for monitoring the water level:

- degree of protection against penetration IP - 68;

- network voltage 220 volts plus or minus 10 percent;

- operating temperature range from 0 to + 60 ° C;

- 8 amperes - maximum switched current for reactive load;

1.3 How does an automatic float switch work? (video)

2 Connection and repair of the float for the pump

Connecting a float switch to systems where submersible pumps are used for pumping water is no different from connecting to drainage, sewer systems. Connection to the pump is carried out in the following way:

- the sinker clings to the wire and experimentally adjusts the length from the sinker to the device;

- the cable should be securely fixed in order to avoid grazing it over pipes and other devices inside the tank;

- if the device is two-phase, then two (or more) units should be used - one for pumping water into the tank, the other for pumping. In wells and self-healing reservoirs, one two-phase can be installed;

- connecting wiring to the pump.

When connected to the pump, moisture proof terminals are used. Wiring and connection points on the pump are indicated, difficulties can arise only with the connection of a two-phase float to a three-phase pump. Two important points for choosing devices:

- The same current consumption in amperes at the pump and the float (or even slightly less at the last).

- The same number of connection phases.

The power of the pump should also be considered.

The device installed in the system can be connected to the float in two ways:

- if its power is less than 1.2 kilowatts, then the connection goes directly through the network wire;

- if the power is higher than 1.2 kilowatts, in this case, the connection occurs through an electromagnetic relay or other switching element.

Many faults are caused by pollution. It is not difficult to repair the float from the submersible pump in the event of clogging. To do this, just pass a stream of clean water through it. If, after disassembling and cleaning the float, its functions have not recovered, and the damage is not noticeable, it is recommended to replace the mechanism with another, since complex repair often costs the same cost.

2.1 Do-it-yourself float switch

To make a float for a pump with your own hands you will need:

- 2 cases;

- metal ball;

- two magnets;

- contact plates.

Contact plates are made of copper, tinplate, brass and other electrically conductive material. They should be located on the sides of the body inside, so that the ball, falling between them, closes the contact. For springiness, strips of metal can be beaten with a hammer by putting it on a file.

Magnets are selected from the calculation so that they can not raise the ball, but kept it at an angle of 60-70 degrees, even while being on the back of the device. The case itself can be made of plastic, PCB, any non-conductive material.

The wires are soldered to the contacts with a core section of no more than 2 mm. They are isolated and this structure is placed in a common float housing made of plastic or similar material. The most important thing is to carefully insulate the inner case so that there is no short circuit. Mounting foam is poured into the cavity of the float, and the outer casing is also insulated.

Loops are installed at the ends of the main building. Depending on which loop the cord is connected to - from the side of the contacts or the return - the pump is filling or draining.

2.2

A drain pump with a float switch is primarily adapted to pump rain or waste water from appropriate tanks. The pumping is carried out using two connected pipes - ejector and suction. The most important thing to watch when choosing a unit is the insulation of the wire and the tightness of the plastic box. Upon purchase, the kit comes with equipment for removing mechanical stress from the wires of the device.

There are two types of drainage pump with a built-in float, like the floats themselves, heavy and light, depending on the destination. Lungs are used for drinking or irrigation water. And drainage pumps with built-in heavy float switches are used for sewage treatment systems and clogged, dirty water. The most famous manufacturers: Gileks, Gardena, Grunsfos, Makita, Pedrollo, AL-KO, Karcher, Whirlwind, HERZ.

Technical characteristics of drainage devices:

- productivity from 6000 to 33000 liters of water per hour;

- feed height from 5 to 27 meters;

- power consumption from 200 to 2000 watts;

- weight from 3 to 14 kilograms;

- immersion up to 27 meters;

- cable length 10 meters.

![]()

You can repair the drainage pump yourself if the following malfunctions are found:

- stuck float - physically free;

- fix the shock absorber if the mount is loose (you need to remove the cover and tighten the nuts);

- the impeller is jammed - when ridding the impeller of mechanical impurities, it should not be pulled together;

- problems with the shock absorber - most often it can simply be replaced by yourself;

- the cable frayed and cut off - in this case, it is necessary to palpate the damaged part of the cable inside the insulation and securely fasten it with insulating material.

Do not try to repair the drain pump yourself in case of the following breakdowns:

- the winding burned out due to a short circuit;

- the stock broke;

- the valve broke.

If the equipment is relatively cheap, with the above breakdowns it is cheaper and easier to buy a new one, since repairs can cost about the same cost.

Drainage pumps with float switches are widely used both for domestic purposes and in various fields of industry, construction and agriculture. With their help, it is possible to remove clogs, clean the wells and perform a bunch of useful things. No wonder these pumps are so popular and in demand in the modern market.

From this article you will learn what types of drainage machines exist, study their working principle, structural part, and installation features.

1 Principle of work and features

1.1 Types of float Drainers

Drainers are classified according to their location. Allocate pumps submersible and surface type. There are also units with a vertical float switch.

1.2 Drain pump with integrated submersible float

The submersible drainage apparatus has a sealed housing, which allows it to function when completely immersed in water. Such designs often have more power than surface-type pumps, since they need to raise the pumped liquid to a high height, which requires high pressure.

Compared to surface drainage pumps, the submersible unit has the following advantages:

- The minimum noise during the work;

- High productivity;

- Universality - such pumps are capable of pumping liquids with a large number of mechanical impurities;

The disadvantages include:

- The complexity of the repair, due to a violation of the tightness of the housing during disassembly;

- The need for periodic cleaning of the pump and float switch, as they are very quickly clogged in dirty water;

- Limited - the submersible drainage apparatus is not able to pump out drains from shallow reservoirs (a minimum depth of 30 centimeters is required, so constantly cooling the electric motor with water is required)

1.3 Drainage pumps with integrated surface type floats

In such devices, wastewater is drawn through a sleeve - a rubber hose, or a PVC pipe, which is lowered into the wastewater; the pump casing itself is located on the surface of the soil. The float switch on the extended cable is lowered into the wastewater along with the hose.

The main advantages of such pumps are ease of installation and maintenance. The disadvantages include the noise that the device makes during pumping water. The cooling of the power unit in such devices is carried out by means of the pumped liquid.

1.4 Drainage fecal pumps

Fecal pumps are used to pump sewage from septic tanks and cesspools. In fact, they represent an improved version of a conventional drainer, and can fully fulfill all its functions. A feature of such devices is the increased capacity - since fecal effluents are basically much thicker than ordinary wastewater.

The fecal pump has an additional structural element - a special mesh that grinds large waste. According to the location method, such a device is identical to conventional drainage machines: there is a submersible and surface fecal pump.

1.5 Vertical Type Drainers

Such pumps are equipped with a vertical float switch, which allows automatic pumping of water from enclosed spaces. Most often, pumps with a vertical float are used to drain failed pipelines. If necessary, they can be operated as ordinary drainage machines.

1.6 Major manufacturers

Today, the assortment of drainage pumps in the domestic market is clearly divided into two categories: budget devices, which include various domestic and Chinese manufacturers, and expensive foreign pumps.

An analysis of supply and demand has shown that in the category of budgetary drainage machines, the best option is Malysh pumps, while Grundfos is the leader in the segment of high-quality devices.

2 Steps for connecting drainage pumps

After connecting the float switch to the pump, you must configure it. It is best to do this in a suitable volume of full water tank, and only then give the pump a “battle test”. Connection and configuration are carried out in several stages:

If several drainage pumps, and accordingly several floats, are used in the water pumping system, they are mounted on a rod, the role of which is usually played by an ordinary plastic pipe.

Features of the direct installation of the drainage pump are as follows. To drain the pumped-out liquid, use a hose whose diameter is identical to the diameter of the discharge pipe of the drainage device.

If the hose is thinner, due to an unnatural pressure drop, the drive of the drainage pump with float switches will be constantly overloaded. This mode of operation has a very negative effect on the life of the device.

Under the drainage machines of submersible or semi-submersible type with a lower water intake, it is necessary to substitute some platform (even an ordinary sheet of metal is suitable) so that the pump does not pick up silt and sand from the bottom of the pumped tank.

Submersible fecal pump can be installed directly on the bottom of the septic tank, if it is concreted and has a flat and hard surface.

If the sewer pit is simply dug in the soil, then it is better to hang the fecal pump on a steel cable 15 centimeters from the bottom, since during the operation of the septic tank, the soil at the bottom can soften and absorb the submersible pump.

Before lowering the device into the cesspool, a flexible hose for discharging sewage is mounted on the sewage pump (depending on the nozzle, it can be fastened with a sleeve or thread, if no fastening is provided, fix the hose with a plastic clamp).

If you want your drainage pump to fully work out its working life, it is necessary to carry out preventative cleaning from time to time. It is not required if the submersible pump is used to drain clean water without mechanical impurities.

However, if the device operates in a contaminated environment, such as a sewer pit, once a month it must be cleaned. It is done simply: with a stream of water under strong pressure (from the hose), the pump and the float are washed away from pollution. Thus, the fecal pump must also be cleaned.

2.1 Overview of the design of the drainage pump with a float (video)

To ensure convenient control of the pumps, there are a large number of different devices, among which a float is widely used. Among the features of this device, it should be noted that it can simultaneously perform the function of a water level sensor and at the same time an actuator for controlling the pump. The place of their placement are storage tanks, tanks, tanks, as well as wells, etc.

The space of one such tank is enough to accommodate several floats, and they can solve various problems:

- Monitor the operation of the main pump;

- Ensure the efficient operation of the auxiliary pump;

- Act as an emergency level sensor;

- Used as overflow sensor.

Using similar devices to control the water level, which are used in these systems, it is possible to protect the pumping unit from switching to the “dry running” mode. Also, in the case of filling different tanks, this element allows you to protect them from overflow.

Can highlight several types of floats for pumps:

- lungs;

- heavy.

The former are widespread in water supply and sanitation systems. The latter are mostly used as part of drainage, fecal and rainwater. In stores, these devices are offered with cable lengths of 2, 3, 5, and 10 meters.

Device and construction

An element such as a float switch for monitoring the water level has floating plastic case. It contains an electric switch and a lever that allows you to translate the contacts of the switch. Also included is a steel ball, which, in case of a change in the position of the float, adjusts the position of the lever itself. A cable consisting of three wires is connected to the switch: the first is common, and the rest are connected to the normally closed and normally open contact of the switch.

An element such as a float switch for monitoring the water level has floating plastic case. It contains an electric switch and a lever that allows you to translate the contacts of the switch. Also included is a steel ball, which, in case of a change in the position of the float, adjusts the position of the lever itself. A cable consisting of three wires is connected to the switch: the first is common, and the rest are connected to the normally closed and normally open contact of the switch.

Circuit short circuit provide black and blue wires at a time when the heat is in the lower position. In the case of its transfer to the upper position, the black and brown wires will already act as closing contacts. A prerequisite here is the insulation of the wire, which does not provide connection to the device. It is important to ensure that the lead-in cable has moisture-proof properties, while the design of the plastic box must be leakproof. A mechanical seal is used to seal the cable outlet, and it also has a special device that allows you to remove mechanical stresses in the cable.

Inside the insulated cavity of the cable entry is located polymer resinwhich protects against ingress of water. The chemical properties and heat resistance of the cable housing and sheath, which are made using thermoplastic rubber, are associated with the ability of the float switch to perfectly tolerate interaction with alcohols, uric acid, fecal water, gasoline and other aggressive substances.

Due to the absence of pores on the surface of the plastic housings, no contamination appears on it. At the same time, this feature ensures the sliding of sand, paper and other solids, against which the float switch retains its floating properties.

Sensor Specifications to control the water level:

- Mains voltage, V - 220 ± 10%;

- Maximum switched current, A:

- 8A - for reactive load (pumps, fans, compressors, etc.);

- 10A - for active load (starters, switches, electric heating elements, lamps, etc.);

- Operating temperature range: 0-60 ° C;

- Protection: IP 68.

Benefits

Among all the advantages that a float switch has to control the water level, first of all, it should be highlighted that it is capable of perform the function of a conventional sensor to determine the water level in tanks. Moreover, he successfully performs this task, even despite the fact that for what purpose the capacity is used and how much it has volume. At the same time, this water level control device is able to help make the operation of pumping equipment more convenient. With the help of such a device, the control of the functions of industrial, domestic water supply systems is simplified.

Among all the advantages that a float switch has to control the water level, first of all, it should be highlighted that it is capable of perform the function of a conventional sensor to determine the water level in tanks. Moreover, he successfully performs this task, even despite the fact that for what purpose the capacity is used and how much it has volume. At the same time, this water level control device is able to help make the operation of pumping equipment more convenient. With the help of such a device, the control of the functions of industrial, domestic water supply systems is simplified.

In some cases, it can be used to successfully drain fluid. Also, a float switch to control the water level can be part of the equipment during the construction of sewer communications. Simplicity of work and high efficiency of its application and provided the float switch wide distribution in a wide variety of systems where the task of controlling water arises.

It is worth noting that the ability to provide reliable protection for pumping systems during dry-running operation is not the only positive qualities of such devices. At the same time, with their help, it is possible to avoid a situation when water overflow occurs in containers.

Mounting

To install float switches, you can use one of several methods. Before installing this device, make sure that the current rating used to operate the pump is less than the maximum allowable current value given in technical specifications on this type of float. Among the known methods of mounting a float switch for monitoring the water level, the easiest to implement is placement in the tankproviding for the use of a float with a cable and a special sinker, which is attached to this device.

To install float switches, you can use one of several methods. Before installing this device, make sure that the current rating used to operate the pump is less than the maximum allowable current value given in technical specifications on this type of float. Among the known methods of mounting a float switch for monitoring the water level, the easiest to implement is placement in the tankproviding for the use of a float with a cable and a special sinker, which is attached to this device.

With this installation option, the sinker must be fixed on the cable, and then empirically calculate the length of the free-wheeling shoulder of the float. Using the latch, you need to fasten the weight on the cable. After that, the cable itself must already be firmly fixed on the outside of the tank. Next, they are already moving on to connecting the float switch to the pump. After that, the device can be used for its intended purpose.

The option to install a float for pumps, involving the use of a supply cable, can only be used in situations where there is no risk of hooks or freezes the main device in the tank itself and when only one float is placed in it.

In some situations, it may be decided to install several floats at once to control the water level. In this case, their installation is carried out on a special rod. As the latter, fragments of a plastic pipe are most often used, which must be firmly fixed in the tank. After that, floats are installed on the pipe, and they must be correctly set, adjusted and spaced along the length of the rod so that they do not create difficulties for each other for normal operation.

The cables that go from the float switches to the rod are brought using clamps. When choosing the number of float switches, you should pay attention to the number of pumps or the type and number of protective devices and control panels used. In some situations, the problem of ensuring reliable operation of float switches can be solved by the use of several rods.

When determining the installation scheme of float switches, their number and location, it is necessary each time to take into account the features of their installation location or to focus on the project.

The principle of operation of the float for pumps

Devices such as float switches can provide various schemes for their use, and this also affects their principle of operation.

Water supply system, filling and emptying the tank tank

![]() With this scheme of operation, at the time of ascent, the float de-energizes the pump, which supplies water to the tank. Power on signal only when it reaches the bottom. This situation occurs only with an empty tank.

With this scheme of operation, at the time of ascent, the float de-energizes the pump, which supplies water to the tank. Power on signal only when it reaches the bottom. This situation occurs only with an empty tank.

The float gives a signal to turn on the automatic water supply station when it is on the surface. Shutting down the station can only happen when the float sinks to the bottom with an empty tank.

On the float side, a signal was received to close the valve or valve with a servo actuator at the time of its rise to the surface. The opening of a valve or valve will only happen when it sinks to the bottom with an empty tank.

The work of the float can only be in the control room alert or the operator at the time of its rise to the surface, which will correspond to the filling of the tank. Information about the lack of water will arrive at the moment when the float reaches the bottom.

Sewage system

The fecal pumping equipment will be switched on by the float only at the moment the main control device is raised up. The pump unit is switched on when the control device is immersed to the bottom.

One float can simultaneously serve two pumping units: the first unit can supply water to the tank, provided that the float is in the lower position. At this moment, the other pump is idle. When the float is in the upper position, the second pump is turned on, the task of which is to pump water from the tank. At this time, the pump, which supplies water to the tank, is in an inactive state. Despite its simplicity, the above scheme for the use of a float switch is not effective enough, since this does not exclude difficulties with the regular delivery of water at those moments when the tank is filled.

Operation, maintenance and repair

It is possible to ensure long-term operation of floats for pumps only if the rules for their use are not violated. In a situation where the float switch is part of the water supply and sanitation system, you can not waste time and effort on its maintenance. If this device controls the operation of fecal or sewer pits, it is recommended that at least once a month float cleaning and the pump from pollution, using a stream of water supplied under pressure.

It is possible to ensure long-term operation of floats for pumps only if the rules for their use are not violated. In a situation where the float switch is part of the water supply and sanitation system, you can not waste time and effort on its maintenance. If this device controls the operation of fecal or sewer pits, it is recommended that at least once a month float cleaning and the pump from pollution, using a stream of water supplied under pressure.

This procedure will prevent sticking or sticking of the float to the pump or pressure pipe. The float switch, which due to certain circumstances is not able to perform its main task, is not repairable, therefore, in such situations it is replaced. Specialists of service centers should carry out this work.

Conclusion

In situations where there is a need to ensure the supply of drinking water to the house or the removal of polluted effluents, it is necessary to use in combination with pumping equipment and special devices. Among them, a float switch is quite effective. The benefit of its use is that it controls the amount of liquid in the tank, and, focusing on this, determines the operating mode of the pump unit.

This device allows you to avoid the transition of the pump to the "dry run", which positively affects its service life. In addition to this, a considerable amount of energy is saved, since the float switch allows the pump to be activated only if necessary.