Vacuum pump for pumping air: buy, device, air. Do-it-yourself vacuum pump.

Vacuum pumps are designed to remove air and gases from large volumes and have recently been used in everyday life. With their help, you can organize the storage of products and things in vacuum packages, pickle meat products, pump out gas and steam, as well as liquid. You can buy such an interesting mechanism, although it is quite expensive, but you can do it yourself. Consider the second option - how to make a vacuum pump with your own hands.

Thus, the energy transferred to the liquid can be used to achieve the desired goal: water supply, hydraulic transport, hydraulic drive, etc. because pumps are specifically designed to transport liquids over distances and distances. Different levels, their use has been introduced almost everywhere where the need arises. Such a transport. In industry, pumps are used in various technological processes, supplying a wide range of liquids or for auxiliary purposes for industrial and drinking water supply.

Application

Such devices in everyday life are used to create a vacuum in plastic packaging for storing food and things. When air is aspirated, the container volume decreases, the shell tightly fits the product. With such storage, food does not deteriorate for a long time, and can be stored for some time without freezing.

In agriculture, pumps are used in irrigation and drainage systems, in the water supply systems of rural settlements, farms or directly in the production process, attaching them to various agricultural machines, such as pest control. Since the transport of fluid by the pump implies a continuous flow between the power source and the discharge point, this can only be achieved in a hydraulic installation. Such an installation usually consists of: pipes, fittings, measuring instruments and, of course, the pump as the main element.

When storing things or other soft textile products (blankets, pillows, rugs), there is a noticeable compaction, things become compact, take up less space. With this method of storage, things become inaccessible to moths or molds.

Using a vacuum pump, it is possible to cover parts made of wood, plywood and other building materials with a laminating film.

Pipes are designed to connect the pump to the suction source and to the liquid outlet. For these reasons, the channel that is connected to the suction tank is called the “suction line” and, similarly to what connects the pump outlet to the outlet tank, the “outlet pipe”.

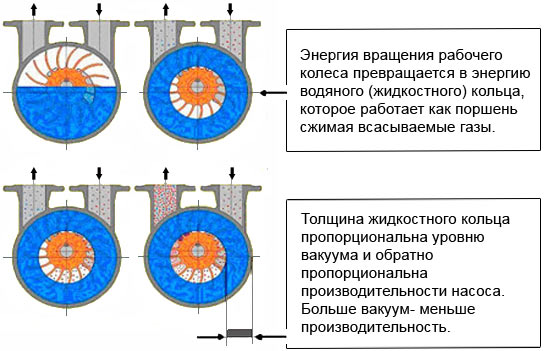

Liquid ring vacuum pump. Pumps are hydraulic machines consisting of an assembly of mechanical elements. which, like other machines in various fields of art over time, have acquired the specific names used today in the world. At the present stage of industrial development, technical solutions chosen for the design of plants include the use of pumps for transporting liquids with a wide variety. features. The category of pumps is represented by liquid ring vacuum ring pumps.

A vacuum pump is used for household removal of gases, steam and liquids, to restore the tightness of household appliances. As well as in split systems of air conditioners and during the operation of brake systems in vehicles.

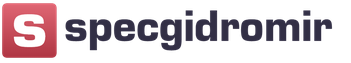

Conversion of cuff pump

These pumps are specifically designed to create industrial vacuums in a variety of applications, but are increasingly being used as blowers or low pressure compressors. This use is particularly desirable since the air flow is continuous and at the same time does not contain oil vapor, as is the case with reciprocating compressors. Liquid ring pumps are part of the type of positive displacement pump. Rotation, which, unlike other volumetric pumps, is able to supply liquid, gas or liquid and gas mixtures without liquid obstacles.

Any cuff pump is useful for alteration, you can even take a bicycle one. However, preferable is still automobile, since with its conversion there will be less trouble.

The sequence of actions for modernization with your own hands looks like this:

- The car pump spins up.

- The cuffs are removed and turned the other way around.

- Then the device is assembled, the only difference is that the cuffs are deployed in the opposite direction.

- At the inlet to the pump, where the hose is screwed through which air will be pumped out, the check valve is screwed. The valve should work, passing air from the tank to the device, but not back. It can be bought or removed from the compressor for the aquarium. Before installation, blow into it. The side that does not let air through is screwed to the pump, the other to the tube.

The capacity of such a mechanism is not enough to obtain deep vacuum conditions, however, for domestic needs it will be quite enough.

Due to these qualities, they are mainly used either as vacuum pumps, or as blowers or compressors, but are less similar to water pumps, given their low pumping efficiency. Vacuum pumps or blowers are used in the chemical industry, as well as in pumping stations, where they serve to charge pumps. centrifuges.

The starter rotor is slidably mounted on a shaft eccentrically located inside the intermediate housing. But the role of the channel here is played by the eccentric position of the rotor on the housing. Scheme of a vacuum pump with a liquid ring 1 - a cylindrical body. 3 - sterile port of aspiration. 5 - liquid ring A vacuum pump with a liquid ring consists of the following elements: And on the other disk there is an unloading window and, in turn, communicates with the unloading casing. 4 - rotor. 1 Design The design of these pumps is similar to the design of pumps with a side channel.

Compressor conversion

A larger vacuum pump is obtained from compressors of household appliances, for example, a refrigerator or an air conditioner. For proper assembly of the device with your own hands, these steps are necessary:

- The compressor is freed from the condenser and evaporator. To do this, have a bite to eat the copper tubes that connect the appliances.

- Ensure that the compressor is properly connected to the network.

- A fine filter is attached to the compressor inlet; it can be purchased at the car dealership.

- We attach a flexible hose of the appropriate diameter to the inlet of the device.

- The compressor is connected to the network and begins to function as a sufficiently powerful vacuum pump.

It is impossible to pump out air with a high content of water vapor with such a pump, this is fraught with a breakdown of the compressor. For such purposes, the apparatus is additionally equipped with a receiver and a sump, which together will serve as a drying device.

Closed side disks. One of the two disks contains a suction window and is connected to the suction casing. 2 - unloading port. 3. casing and side discs. A liquid ring vacuum pump should only work with liquids or clean gases. the liquid in the stator is designed due to centrifugal forces at the periphery of the housing. The pump is assembled using tyrants. The suction casing is provided with an opening for connecting a fluid supply line to a fluid ring. Pump performance depends on the axial clearance between the rotor and the distribution discs.

In the same way, with your own hands, you can convert a simple aquarium mechanism - a compressor, disassembling it and dismantling the check valves, which have already been mentioned in connection with the transformations of a car pump. Swap the valves, then instead of pumping air, the compressor will pump it out.

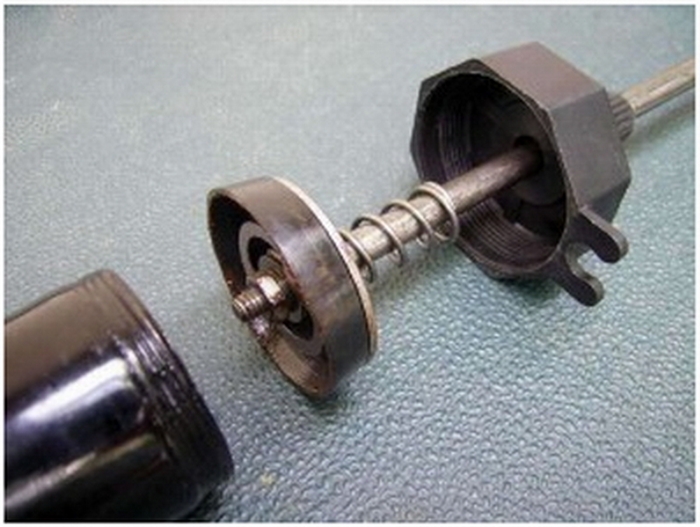

Medical syringe conversion

The rotor of a vacuum pump with a fluidized bed is similar to a rotary pump with a side channel. The bearings are made of cast iron. The inner surface of the fluid ring and the side covers of the pump. At the time of starting the pump. The rotor can slide on the shaft, self-centering in the housing, and because it can come in contact with the disks. a game that should not exceed values \u200b\u200bin the form of molded parts. The plugs are used to drain the liquid pump during periods of frost. generating a fluid ring having a constant thickness and concentrically located with the pump casing.

There are also reasons for such an invention - curious children or small volumes of liquid and gas that need to be pumped out. To make the device yourself, you will need the following set of parts:

- Plastic tee.

- A flexible plastic tube matching the diameter of the inlet of the syringe and the holes of the tee.

- Two aquarium check valves.

- Medical syringe, the larger its volume, the more powerful the pump will be.

We cut a plastic tube into segments of 10 centimeters in size and attach to the tee. The tubes must tightly and tightly fit the nose of the tee, so as not to come off when working under pressure. We leave two opposite tubes alone. To the third, which is located at right angles, we attach the nozzle of the syringe. Thus, the design is a tee with two pieces of hoses, allotted in different directions and a syringe located at right angles to the allotted ends.

Washed with a sealing fluid. Variable displacement volumes are formed between the rotor hub. its side and surface of the disc are very thin in order to obtain reduced roughness. The pump shaft rests on both ends on two ball-bearing bearings. The correct position of the discs is ensured by the centering pins. A crescent-shaped space is formed. wheels. therefore, gases containing dust will be filtered prior to absorption. During work. Due to the eccentric position of the rotor.

The shaft seal is provided with soft graphite asbestos. From the vertical axis. So these pumps can deliver a significant amount of fluid. thus providing the necessary vacuum for suction through the suction groove. and to this category of pumps. Because the transportation of liquids with such pumps is carried out with a low output. And the intake air begins to compress and is discharged through the outlet. A certain amount of liquid is also removed through the discharge gap. Unlike side channel pumps.

The next step is the installation of check valves. Usually they have a marking and a pointing arrow. We insert one of the valves so that the arrow points from the tee, the second one. So that the arrow points to the tee. In general, the system will resemble an input-output pointer.

The hand pump is ready. They can be diverted water from one vessel to another by immersing one valve in water and the other in a container where it is supposed to pump liquid. In this case, the pointing arrows are guides. A valve with a pointer to a tee is immersed in the liquid. With the movements of the plunger of the syringe we can make the system work.

In close proximity to the side covers. When the direction of rotation is shown in the figure above. The volume of these cells decreases. The choice of the connection of the working volume with the suction or exhaust pipe is carried out using distribution discs located on one side of the rotor. where part of the piston is captured by the fluid ring. Sizes are no longer limited. which leads to a decrease in the thickness of the liquid ring and to a pump malfunction. The pumping process is due to a change in volume. They are especially used for evacuating air or gas from different containers and installations.

Low vacuum pump

Such a pump operates on a centrifugal principle. It is difficult to do it yourself, however, if you have a familiar welder and turner, it is quite possible. To create it, you need to have a cylindrical body into which a shaft with a paddle wheel is inserted. When the liquid is supplied, the rotation of the impeller begins and, under the influence of centrifugal force, a vacuum is inevitably created in the center of the device.

To fill the amount of exhaust fluid and 5. to the liquid ring vacuum pumps. The rotor is mounted on the shaft with stroke adjustment, which allows self-centering between the cover and the distribution disk. where the side channel section limits the size of the pump and therefore the hydraulic parameters. cell volume increases to the vertical axis of the rotor. With the evacuation of air from the cells.

The main advantages of liquid ring pumps are: The supply liquid is constantly cooled to prevent evaporation. These pumps may be one or more stages. No vibrations. To create a vacuum. Liquid ring vacuum pumps are used in various technological processes or as central soil pumps for pumping stations. The air is getting warmer. Constant flow. as well as air compressors. They are used as pumps for centrifugal pumps.

The mechanism is driven by an electric motor. The impeller wheel is not set completely in the center to allow forcing and pushing gas through the system. The disadvantage of the system is that the liquid with which the process is carried out (more often it is water) is constantly heated and it has to be changed.

Such a pump is provided with inlets through which water enters and outlets through which gas is discharged.

Therefore, the power source must be from a source that has an appropriate temperature. No ripples. Multistages produce high vacuum. Due to the compression process performed in the pump cells. The characteristic curves of liquid-ring vacuum pumps are indicated by suppliers at a temperature of the working fluid of 15 ° C, and they can vary depending on the temperature change of the latter. 700 mmHg for the vacuum achieved. But in this mode, the flow decreases to zero. In the same time. This provides high reliability and minimal wear.

Mechanisms operating in this way are used in large enterprises, as well as in agriculture, to remove gases with a large amount of suspended matter in the form of dust and sand. For continuous operation, a gas outlet, a constant water supply and a motor cooling system are provided.

The simplest vacuum pump

Such pumps are called "self-priming centrifugal pumps." The diagram below shows the characteristic curve of a liquid ring vacuum pump. Thus. with modified slots. Liquid ring vacuum pumps are also used in combination with centrifugal pumps. When the suction pressure is equal to atmospheric pressure. Without functional defects. To get these options. And buckets can reach values \u200b\u200bof 6-7 bar. Using the same discs with which the vacuum pump is installed will have lower performance and reduced outputs.

Since the simplest vacuum pump may be needed at any time, you can make it in the most elementary way from plastic bottles of different diameters. It will be a primitive vacuum pump, a home-made manual mechanism.

For manufacturing you will need:

- Two bottles that easily fit together. One of them will be a piston, so you need to pick up bottles that are not too different in diameter, otherwise you will have to make a serious layer of sealant on the inside.

- Hose from a bicycle pump.

For a larger bottle, cut off the top. We make holes in the bottom of a smaller bottle. We insert the bottles into each other, on the inner bottle we make a sealant from adhesive tape, if necessary. Screw the bicycle pump hose into a large bottle, in the opposite direction. So he will pump air when the piston moves from a small bottle.

That is an ordered stream. The location of coordinates is similar to the location of volumetric pumps 760 mm RT. But it increases as the vacuum grows. 8. Pump specifications may also be indicated for normal gas conditions. As the vacuum grows. In this category of pumps. And the attractiveness of the yield curve is similar to that of other categories of pumps. The flow of auxiliary fluid is constant in the medium vacuum region. Under these conditions, the allowable tolerance for the flow is 10%. The suction air flow is considered to be attenuated in an appropriate vacuum.

The main types of vacuum pumps:

- Water ring devices - work is ensured by immersion in a fluid of a mechanism, which, rotating, creates a vacuum in the center of the chamber of the blade mechanism.

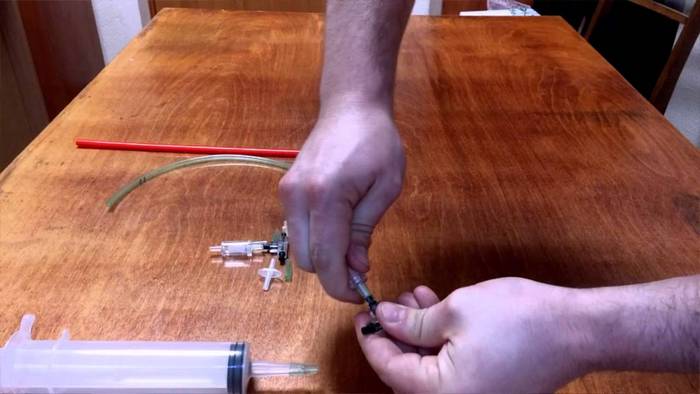

- Rotary vane Vacuum devices are usually two-chamber, and operate on the principle of pumping gases from one chamber to another, which is ensured by the operation of the rotor mechanism.

- Diaphragm piston vacuum apparatuses - vacuum injection is ensured by the operation of the piston system; during compression, the gas is discharged outside the chamber through the valve, which ensures a decrease in pressure in the chamber and the arrival of a new portion. Such piston pumps are among the most silent and versatile.

Vacuum pump in the home

The absorbed power increases in parallel with the increase in vacuum. The overall output of liquid ring vacuum pumps is also low. Compared with centrifugal pumps, reaching current design values \u200b\u200bnot exceeding 40%. And abscess is pressure.

This is explained by the increase in losses in the gaps in higher vacuum modes. The conversion of values \u200b\u200bfor the normal state is carried out according to the Boyle-Mariotte law. That is, at first it rises until it reaches its maximum value. Become a descendant. After that, he becomes a descendant. that. Therefore, their design is different from the pump than the compressor. The diagram shows that the optimum range of use differs from the vacuum pump by the compressor. The rest of the songs are shared. Some construction companies have the characteristics of liquid-ring vacuum pumps in tabular form.

Vacuum pumps are designed to create a rarefied space in separate volumes. It can be either plastic bags in which you are going to store food or warm clothes, or Split systems of air conditioners. The system of vacuum braking in vehicles significantly increases the life of the vehicle.

Or in the form of diagrams, where the flow is determined in kg of air drawn into the working state. so that both functions of a liquid ring machine can be represented in a common diagram. This is a vacuum pump. Therefore, the operation becomes uneconomical. The characteristic curves defined for the pump to operate as a blower or compressor are plotted on the left side of the ordinate axis. For high vacuum up to 25 mmHg and pumps in combination with an air ejector. For vacuum up to 5 mmHg.

Consequently, a wide range of materials. The plant has no contact with the environment. With the following features. Pumps are used in all areas where the pressure is 33. Closed systems Consider a closed thermodynamic system. Due to the exchange of energy with the environment. The amount of energy exchanged with the environment. For instance. A heat agent receives heat and performs mechanical work. The figure shows the first principle of thermodynamics applied to a closed system. The system is open because the working fluid passes through the machine.

At first glance, it seems that there is no urgent need for vacuum systems in everyday life. And indeed it is. However, try to assemble the simplest vacuum pump with your own hands and you will be surprised how many ways to use it.

For the implementation of most chemical processes, it is necessary to create certain conditions, one of which is the lack of pressure inside a separate system. It is based on a vacuum pump. This device is used in many areas of production: chemical, oil and gas and other types of industry, where through it air is pumped out in a closed system, thereby bringing the pressure level to zero.

The vacuum pump works according to the following principle: its moving part periodically changes the volume of the inner chamber. A fairly wide variety of similar devices are presented on the modern market, differing in design, purpose, a number of technical parameters, and so on. For example, the working part has several options depending on the type of pump.

That is why it is worth considering what products are and what are the features of each of them.

Types of Vacuum Pumps

The following types of vacuum pumps can be found on the market today:

Plastic rotary with oil seal

This pump has the advantage over other similar units in that it creates a vacuum in the range from 0.1 to 800 mbar. At the same time, in one hour of operation, the device pumps out from 4 to 1600 cubic meters. air.

The pump is based on a rotor. It is he who is responsible for pumping air. 2 plates are attached to the rotor, pressed against the side walls by means of springs.

The most popular is a two-stage plastic rotary pump. Due to the presence of 2 chambers (air is supplied first to the first and then to the second, after which it enters the output manifold), such an aggregate creates a more rarefied medium. However, single-stage pumps find their application.

Dry rotary vane or oil-free

The vacuum created by the pump is in the range of 100-1013 mbar. In an hour, the unit pumps out from 3 to 500 cubic meters. air. A feature of such a device is that its operation does not require oil. That is, all evacuated air is not further contaminated with oil vapors. In addition, it is not necessary to regularly treat structural elements with grease.

In the latter, the main drawback of such pumps lies precisely. First of all, the lack of lubrication affects performance. In addition, the unit heats up faster, which means that it should be turned off for a while to cool. And, in the end, the owner often has to change the working blades.

A dry rotary vane pump is used mainly in those areas where it is necessary to exclude the possibility of oil droplets falling onto products (food production, printing, and so on).

Cam

Cam pumps are capable of creating a vacuum of up to 200 mbar. Their productivity is 950 m3 / h. Such sediments evacuate air with the help of 2 "cams" rotating relative to each other. Between them moves the working environment.

Like the previous ones, cam pumps do not require lubrication. Therefore, they have similar limitations: they quickly heat up, frequent replacement of elements and a low level of vacuum created.

Water ring

In an hour, water ring units pump out up to 300 cubic meters. air, creating a vacuum in the range from 33 to 1013 mbar. They have a simple construction and are able to work with contaminated and hazardous flows.

Despite the fact that such pumps are the first such invention, they are still not out of use. At the same time, water supply and a sufficiently large amount of electricity are required for their operation.

The design of the unit includes a round drum, in which a rotor with mounted blades is located. To operate the pump, it is necessary to partially fill this drum with water. When it turns on, the liquid is distributed along the walls under the action of centrifugal force.

The rotor itself is located at some distance from the central part of the drum, due to which a cavity is formed around it, divided by the blades into several cells. After starting the pump, the rotor begins to move, due to which a pressure difference arises between the indicated cells, due to which air is sucked in.

Piston

Piston pumps are usually compact in size. The performance of such units is measured in liters per minute and is in the range of 3.3-78. Despite their dimensions, piston pumps create a fairly good level of vacuum, and are also able to replace the compressor.

Among the disadvantages of such devices emit a high level of noise created during operation. In addition, the pistons that are responsible for the change in pressure quickly fail. The scope of such pumps are usually research and development.

How to choose a vacuum pump

When choosing a vacuum pump, attention should be paid to its main characteristics:

Pressure

The pump parameters indicate 3 types of pressure:

- Exit pressure, or pre-vacuum. This indicator is important at the outset.

- Working. It is an input indicator, determined depending on the specific conditions in which the work is carried out.

- The ultimate, or ultimate. The pressure level obtained in closed containers.

Speed

It shows the amount of air pumped out per unit of time at a given pressure.

The volume of fluid required to cool the pump.

Power consumption

This indicator demonstrates both the level of electricity consumption and the amount of liquid used for cooling.

When deciding on the choice of a pump, it is first necessary to understand for what specific purposes the apparatus will be used. It is also important to find out what pressure is required, and with what volumes of air the device will work.

For example, piston pumps have a fairly simple design, are easy to use and are capable of pumping flows that contain a small amount of liquid. Due to such features, they are in demand in the chemical industry. In addition, piston pumps are suitable for industries where it is necessary to set the pressure at the level of 5-100 mm Hg. Art.

For distillation, drying and other similar processes, rotary oily devices are used. The main feature of such devices is that they are able to create reduced pressure (starting from 0.001 mmHg) and pump out air in large volumes. Additionally, such pumps are equipped with gas ballast or other equipment. However, an important condition for their operation is the complete absence of any liquid in the pumped out air.

One of the most popular is the rotary vane pump. They are less demanding on operating conditions, easy to handle. In their design, plates are provided by which it is possible to remove large masses of air. Such pumps are often used in the chemical industry to create a preliminary vacuum.

Prices for vacuum pumps for pumping air

Since the market offers a fairly wide range of vacuum pumps, respectively, their price between individual models can vary significantly. Today, the cheapest unit is estimated at about 2-3 thousand rubles. At least 5 thousand rubles will have to be paid for a water ring pump.

For example, the device NVR-16DM, capable of pumping up to 16 liters in one second, will cost 35 thousand rubles. 10 times cheaper (3.5 thousand rubles) is 2NVR-01D. True, he pumps only 0.12 liters per second. Between them, at the price, you can position the BBH1-0.75 unit. Its cost is 15 thousand rubles, and the maximum productivity is 0.75 cubic meters / min.