Vacuum pump for pumping air out of the compressor. We make a vacuum pump for water with our own hands.

To obtain a vacuum of one degree or another, appropriate devices, called vacuum pumps, are needed. These systems, offered today, are used to remove vapors or gases to a specific pressure level.

In the article we will talk about the purpose of the vacuum pump, the principle of operation, its types.

1. General Provisions

Vacuum pumping units are units designed to pump out air, gas, steam, which circulate in a closed system. Due to this pumping, a rarefied medium or a medium with a reduced pressure is formed, i.e. vacuum. The main industry used by these devices is industrial, but in everyday life they also found their application.

Electronically controlled gas heater

Electronically controlled gas heaters are equipped with precise electronic regulation, which guarantees economical operation. The furnaces are also equipped with a timer for switching on according to the set time. You need to connect to the grid.

Gas stove and gas heaters

Karma stoves and heaters with exhaust fumes in a chimney or through a wall. A gas heater can be used to burn natural gas and propane-butane. Heating elements, both suspended and stationary.1.1 Purpose of vacuum devices, principle of operation

The most important unit of any vacuum system is mainly designed for pumping air, while creating the necessary pressure, which is not necessary in all cases to be increased. So, for example, for the implementation of certain chemical processes, a necessary condition is a decrease in pressure or the creation of a vacuum. It is with this operation that the vacuum pump copes. Heavy industry, oil and gas, chemical and metallurgical - in the first place, they need such devices.

Gas boilers in stationary and overhead versions. Boilers for solid fuels, for burning wood, coal, pellet boilers. The boilers have a built-in fan, traction control. Peller boilers are manufactured in a fuel tank design. Built-in and stationary fireplace stoves and ovens. Gas gas stove for natural gas or propane-butane Karma. Wood stove with heat exchanger, stove Eliza. Fireplace stoves can be used as the main or additional source of heat.

Electric heaters and infrared heaters

Electric air heaters and electric radiators in rooms and bathrooms. Electric infrared radiators on the terrace, in the outdoor environment. Storage furnaces for space heating as the main or backup heat source by heat storage.

The principle of their work is to remove gases from the working sealed chamber, periodically changing its volume. A vacuum pump for pumping air leads to the distribution of molecules of a natural gas mixture in a closed system. Thus, the units operate by the displacement method.

Interesting fact. The technology underlying the pumps is similar to the one that makes air compressors work.

Cleaning and protective fluid for heating, solar system for cleaning and protecting the heating system. Solar system and solar installations for heating and hot water. Tubular or flat solar panels. Solar assemblies contain all the components needed to connect.

Wall conditioners

Wall-mounted air conditioning is equipped on the wall.

Cassette Air Conditioners

The cassette unit is installed in the lower ceiling, so it takes up almost no space. The window sill is designed for installation on a wall, under a threshold or on a fixed installation on the ground. The ceiling unit creates the effect of heating the floor at its location.Underground air conditioners

Ceiling ceiling air conditioning. The blocks under the ceiling are compact.

Installations provide two basic conditions:

- reducing the pressure level to the minimum value due to the intake of the gas mixture from the environment of a closed system;

- ensuring the efficiency of this process.

1.2 Key Features

The appearance of varieties of vacuum pumping equipment is affected by technical parameters. The main characteristics of vacuum technology include:

Duct air conditioners

The channel channel is suitable for both horizontal and vertical installation. Therefore, it is installed in the ceiling, ceiling, etc. channel blocks are equipped with a condensate drain pump.

Outdoor air conditioners

Outdoor air conditioners work on the principle of a heat pump. The outdoor inverter unit is suitable for air conditioning and heating. The outdoor units are equipped with a variable speed motor, a frequency converter, which guarantees high efficiency and silent operation.Office air conditioning with remote control

Office air conditioning and work with a remote or wall controller. Commercial air conditioners are located in wall-mounted air conditioners, cassettes and ceiling air conditioning, air conditioning duct. Separate office air conditioner with one outdoor and one indoor air conditioning. Wall, ceiling, cassette and air heaters are equipped with a remote control.

- Pumping Speed \u200b\u200b( S r) is the volume of air pumped out at a fixed pressure per unit time.

- The speed of the pump ( S m) - i.e. value, which is characterized by the efficiency of the fence in the input section of the unit.

- Performance ( Q m) is the flow of a natural mixture of gases pumped out per unit time through the inlet section of the vacuum apparatus.

- Power consumption and volume of liquid poured for cooling by the pump mechanism.

- Highest starting pressure ( p zap) - this is the greatest pressure at the pump inlet, bringing it into action.

- The highest release pressure ( p vyp) - the maximum value of the pressure in the outlet section, ensuring the pumping process.

- The greatest working pressure ( p b) - an indicator of the greatest degree of elasticity of the gas at the pump inlet, which maintains the nominal speed of action for a long time. In the operating range (from the smallest value to the largest), efficient operation of the mechanism is ensured. The range of operating pressure values \u200b\u200bis determined by the design and operation principle of the pumping equipment.

- Residual Pressure Limit ( p pr) - the smallest value to which the pressure in the test set volume approaches without gas release during normal operation of the vacuum device.

- Lowest working pressure ( p m) is the minimum pressure indicator at the pump inlet, due to which the device retains the necessary speed of action for a long time. Typically, the lowest working pressure is an order of magnitude greater than the maximum.

- Time to exit to operating mode ( t out) - the period from the moment the unit is turned on to the moment when it starts pumping out at operating pressure.

2 Types of vacuum pumps

The principle of operation depends largely on the type of device, therefore it is advisable to consider the existing types of pumps that pump air.

Air conditioning in the office, work or shop using a wall-mounted wired controller. Air conditioning in wall, cassette, duct or ceiling air conditioning. The air conditioning unit is a condensate drain pump.

Wall-mounted multi-split air conditioning in the house and apartment

Cassette air conditioners are compact, so they can be used in homes, offices, operations. Multilayer wall-mounted air conditioners are installed on the wall of the apartment building. Room air conditioners are equipped with filters, a timer, an ionizer. Wall blocks are highly efficient. The multi-split air conditioner is equipped with a remote control for each device. Wall-mounted air conditioning has a modern design.

The most common classification is as follows. To obtain medium and low vacuum, a mechanical type of pump is used. These include two-rotor, liquid-ring, plate-rotor, plate-stator, turbomolecular, piston.

Console parapet air conditioning in the house

The parapet threshold assembly can create the effect of underfloor heating. Duct air conditioners are installed in the ceiling, ceiling cassette, ceiling, etc. ducted air conditioning saves space because the air conditioner itself is built-in and covered with an exhaust grill. Duct air conditioners are suitable for homes, offices, apartments. Duct units can be embedded in relatively small and low spaces due to their low height and depth.

Floor conditioning to home, office, apartment

Underfloor air conditioners are suitable for false ceilings, etc. Ceiling air conditioners have an aerodynamic shape, which makes them minimal in space, which makes space unnecessary. Underfloor air conditioning can be found in offices, homes and operations.

2.1 Rotary vane pumps

Lamellar-rotor basically have a rotor rotating 2 plates, which are pressed by a spring to the edges of the chamber. They are divided into one, and two-stage. The difference lies in the quantitative equipment of the cameras into which the removed air enters. Two-stage devices, unlike single-stage ones, create a low pressure of increased value. (The maximum residual pressure of a single-stage is 1.33 Pa, of a two-stage is 0.133 Pa).

Wall-mounted wall-mounted air conditioning is easy to install. Parapet air conditioning is installed suspended on the wall or fixed on the floor. Console air conditioning creates the effect of underfloor heating. Cassette air conditioning is installed in the ceiling, so it saves space. Air conditioners have the ability to control the direction of air exhaust through the panel included in the delivery.

Air conditioning duct for ceiling or ceiling installation is compact. All parts of the air conditioner are integrated in the ceiling or mesistrop. The air conditioning device in the duct includes a condensate pump and a remote control.

The lubricant is oil, the use of which significantly extends the life of the mechanism, preventing the working bodies from overheating. Pumping speed ranges from 0.21-3 l / s. Productivity 4-1600 cu. m per hour.

Air conditioners are divided into apartments and houses

Underfloor air conditioning does not take up space, so it is suitable for apartments, houses, offices, offices. Split air conditioners are suitable for installation in apartments or houses. The air conditioner unit consists of an indoor and outdoor air conditioner. We offer split air conditioning for cooling and heating. Air conditioners have built-in filters for air purification, protection against bacteria.

Multi-split air conditioning is suitable for a home or larger apartment. Air conditioning can also be used in offices and operations. The multi-split air conditioner has a separate control unit, so each indoor unit can work independently. We offer air conditioning with various rooms, wall-mounted air conditioning, parapets, ceiling cassette and air conditioning.

Lamellar-stator are used to create the initial fore-vacuum pressure at the pump inlet, preliminary rarefaction in the system.

2.2 Turbomolecular products

To obtain a “oil-free” high vacuum, turbomolecular pumps that were widely used were designed. They are an axial multistage compressor with elements such as stator disks rigidly mounted on the housing, rotating disks placed on the rotor. Disks with radial grooves make up the working mechanism of the pump.

Air conditioning in the office and on the Split highway

Air conditioning Split with remote or wall control.

Office air conditioning and synchronized operation

Synchronous air conditioners are suitable for installation in offices and operations. Air conditioners have a common internal control unit for general settings. Air conditioning in the office is available in wall, cassette air conditioners, ceiling air conditioning, duct and parapets.Outdoor air conditioners - heat pumps. The remote control is equipped with indoor units. The recovery unit guarantees uninterrupted ventilation and air exchange in office premises. The heat recovery unit contains a heat exchanger that generates heat or cold from the air and passes air from the environment to ensure a constant room temperature without heat loss.

Rotor rotation at a speed of over 1000 rpm. provided by electric motor. In their arsenal there are a number of advantages: pumping out condensable vapors, resistance to a sharp increase in pressure; quick start, high degree of air compression, high ultimate vacuum (reaches up to 10 -7 Pa). However, there are drawbacks - this is the complexity of the device, the need to disassemble the entire structure during cleaning, large dimensions, high price.

Gas flow heaters in the chimney

In the exhaust heater of the chimney installation of chimneys is required. Heaters with an open combustion chamber emit combustion air from the room where they are installed, so the room must be ventilated. Ceiling heaters can be installed in residential areas.

Turbo-gas flow heaters

Flue gas is fed through a coaxial pipe. The water heater draws in combustion air from the outside. The turbo heater has a closed combustion chamber.

Natural gas flow heater

A natural gas heater burns standard natural gas. Heaters are equipped with gas burners. Natural gas heaters can be exhaled in the chimney, with or without drainage through the wall. Propane-heaters for propane-butane. Propane-butane water heaters are adapted for burning gas from gas cylinders.2.3 Liquid ring mechanisms

Liquid ring mechanisms are considered the oldest type of vacuum pump. The design includes: a drum partially filled with water, a rotor with blades. During its rotation, a centrifugal force acts on the liquid, as a result of which water is pressed against the inner walls of the drum. Ring-type electric pumps are time-tested, but consume a lot of energy, so they lose their popularity. Plus - ease of operation and design.

Electric instantaneous heaters with battery

Heaters have special nozzles for burning propane-butane. They are made in versions in chimneys, turbo-heaters through the wall or without flue gas. The flowmeter is designed for one or more sampling points that are not used simultaneously. We offer a water heater with a plumbing, lever or shower.

Heaters are suitable for wet environments. These instantaneous heaters are suitable for one or more supply points. Ceiling heater can be installed in the shower, kitchen, bathroom, etc. The water heater has three spirals, which ensures very fast heating of water even in high demand. Ceiling heaters have the option of heating at a low energy tariff.

Productivity is 300 cubic meters per hour, the produced vacuum is in the range of 33-1013 mbar. Units are capable of pumping out contaminated and dangerous flows.

2.4 Household vacuum devices

A household vacuum pump is a small-sized device that pumps air from food containers, as well as bags and other containers.

Storage tanks without exchanger

Tanks have built-in connections for several sources of hot water.

Storage tanks with one exchanger

Tanks have built-in tubular heat exchangers. Storage tanks with two heat exchangers. The tank is equipped with two tubular heat exchangers for heating water from two or more heat sources.Storage tanks in a tank with one exchanger

Storage tank, tank tank system. An external tank heats the water in the internal tank. The heat exchanger is located in an external or internal tank.

Storage tanks in a tank with two heat exchangers

A tank for connecting two external heat sources. Each tank is equipped with a heat exchanger. An enamel tank can be used as an indirect water heater.

Thanks to it, an airless space is formed, as a result of which food products do not interact with oxygen and have a long shelf life. Household appliances are sold in retail chains and household appliances stores. Since evacuation remains the most natural and harmless way of storing products, aggregates have been created that create a vacuum for cans.

Tubular Heat Exchanger Heaters

Double Coil Heat Exchanger Heaters

Substandard boilers with a double jacket heat exchanger can be used in closed heating systems, but are mainly suitable for open systems. Water heaters with one heat exchanger. Boilers offer the option of installing an electric coil for direct heating.Water heaters with two heat exchangers

Heat exchanger boilers with two heat exchangers are designed to heat hot water by combining two external heat sources, a boiler, and a solar system. Boilers have the ability to install an electric spiral. Combined water heaters with a tubular heat exchanger are especially suitable for closed circuits with forced circulation of water.

Thus, the VAKS system offers simple and reliable hand pumps for capping cans with vacuum caps. The popular HBP-3 provides vacuum to a depth of up to 80%, 4 types of vacuum-type covers.

2.5 How to create a manual pump at home?

It is not difficult to create a manual vacuum pump for pumping water with your own hands. A relatively large pipe is suitable as a working chamber, its diameter should be 20-30 cm. A plate (such as a flange) should be welded to it from below. Then, using connections, for example, a counter flange, it is attached to the casing. Make holes in the side chamber that allow water to escape. The pipe outlet is welded to the same place.

A check valve made of rubber is installed at the inlet section of the chamber. The next step is to connect the metal lever to the second rubber valve, which should be located at a level of 15 cm below the area used to withdraw water. In conclusion, you need to connect the pressure lever and the headquarters.

2.6 Estimated Rates

If you are looking for vacuum pumps, information on prices for units of this category will not be superfluous. The minimum cost will be in the range of 2000-4000 rubles, the liquid-ring is more expensive - the most budget model will cost 5000 rubles and above.

Here are some specific examples:

- VVN1.075 - the device pumps 0.75 cubic meters per minute, the price is 15,000 rubles;

- HBP-16DM costs approximately 35,000 (16 l / s);

- a turbomolecular pump manufactured by Edwards EXT75Dx with a pumping speed of 42 l / s - 71604 rubles;

- BC-VP-215 (2 steps, 43 l / min) - 7805 rubles;

- 1DS-115S with a pumping speed of 42 l / min - 5900 rubles;

- two-stage unit V-i2120 (340 l / min) - 34,000 rubles.

2.7 Homemade compressor and vacuum pump (video)

Vacuum pumps are designed to remove air and gases from large volumes and have recently been used in everyday life. With their help, you can organize the storage of products and things in vacuum packages, pickle meat products, pump out gas and steam, as well as liquid. You can buy such an interesting mechanism, although it is quite expensive, but you can do it yourself. Consider the second option - how to make a vacuum pump with your own hands.

Application

Such devices in everyday life are used to create a vacuum in plastic packaging for storing food and things. When air is aspirated, the container volume decreases, the shell tightly fits the product. With such storage, food does not deteriorate for a long time, and can be stored for some time without freezing.

When storing things or other soft textile products (blankets, pillows, rugs), there is a noticeable compaction, things become compact, take up less space. With this method of storage, things become inaccessible to moths or molds.

Using a vacuum pump, it is possible to cover parts made of wood, plywood and other building materials with a laminating film.

A vacuum pump is used for household removal of gases, steam and liquids, to restore the tightness of household appliances. As well as in split systems of air conditioners and during the operation of brake systems in vehicles.

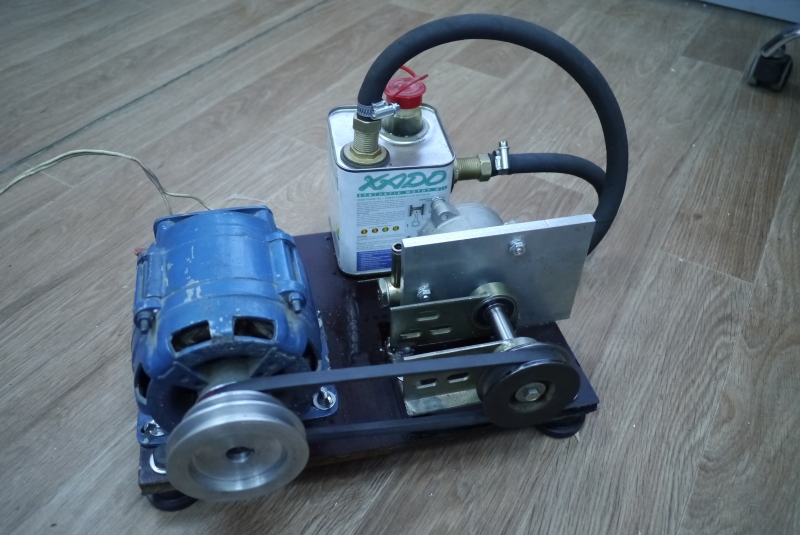

Conversion of cuff pump

Any cuff pump is useful for alteration, you can even take a bicycle one. However, preferable is still automobile, since with its conversion there will be less trouble.

The sequence of actions for modernization with your own hands looks like this:

- The car pump spins up.

- The cuffs are removed and turned the other way around.

- Then the device is assembled, the only difference is that the cuffs are deployed in the opposite direction.

- At the inlet to the pump, where the hose is screwed through which air will be pumped out, the check valve is screwed. The valve should work, passing air from the tank to the device, but not back. It can be bought or removed from the compressor for the aquarium. Before installation, blow into it. The side that does not let air through is screwed to the pump, the other to the tube.

The capacity of such a mechanism is not enough to obtain deep vacuum conditions, however, for domestic needs it will be quite enough.

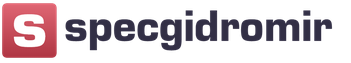

Compressor conversion

A larger vacuum pump is obtained from compressors of household appliances, for example, a refrigerator or an air conditioner. For proper assembly of the device with your own hands, these steps are necessary:

- The compressor is freed from the condenser and evaporator. To do this, have a bite to eat the copper tubes that connect the appliances.

- Ensure that the compressor is properly connected to the network.

- A fine filter is attached to the compressor inlet; it can be purchased at the car dealership.

- We attach a flexible hose of the appropriate diameter to the inlet of the device.

- The compressor is connected to the network and begins to function as a sufficiently powerful vacuum pump.

It is impossible to pump out air with a high content of water vapor with such a pump, this is fraught with a breakdown of the compressor. For such purposes, the apparatus is additionally equipped with a receiver and a sump, which together will serve as a drying device.

In the same way, with your own hands, you can convert a simple aquarium mechanism - a compressor, disassembling it and dismantling the check valves, which have already been mentioned in connection with the transformations of a car pump. Swap the valves, then instead of pumping air, the compressor will pump it out.

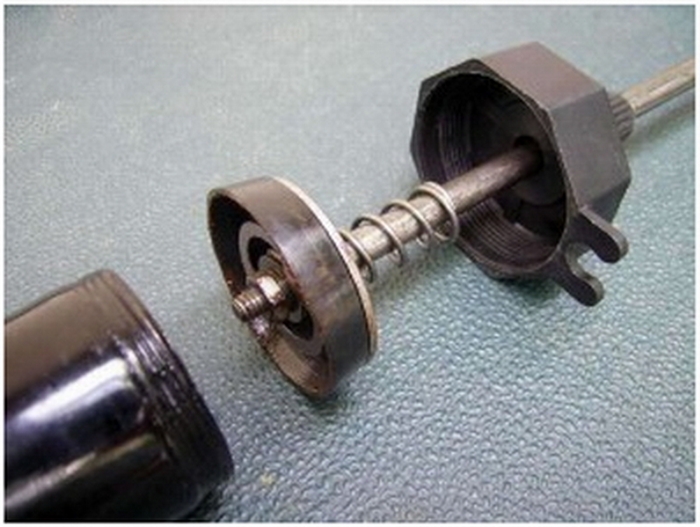

Medical syringe conversion

There are also reasons for such an invention - curious children or small volumes of liquid and gas that need to be pumped out. To make the device yourself, you will need the following set of parts:

- Plastic tee.

- A flexible plastic tube matching the diameter of the inlet of the syringe and the holes of the tee.

- Two aquarium check valves.

- Medical syringe, the larger its volume, the more powerful the pump will be.

We cut a plastic tube into segments of 10 centimeters in size and attach to the tee. The tubes must tightly and tightly fit the nose of the tee, so as not to come off when working under pressure. We leave two opposite tubes alone. To the third, which is located at right angles, we attach the nozzle of the syringe. Thus, the design is a tee with two pieces of hoses, allotted in different directions and a syringe located at right angles to the allotted ends.

The next step is the installation of check valves. Usually they have a marking and a pointing arrow. We insert one of the valves so that the arrow points from the tee, the second one. So that the arrow points to the tee. In general, the system will resemble an input-output pointer.

The hand pump is ready. They can be diverted water from one vessel to another by immersing one valve in water and the other in a container where it is supposed to pump liquid. In this case, the pointing arrows are guides. A valve with a pointer to a tee is immersed in the liquid. With the movements of the plunger of the syringe we can make the system work.

Low vacuum pump

Such a pump operates on a centrifugal principle. It is difficult to do it yourself, however, if you have a familiar welder and turner, it is quite possible. To create it, you need to have a cylindrical body into which a shaft with a paddle wheel is inserted. When the liquid is supplied, the rotation of the impeller begins and, under the influence of centrifugal force, a vacuum is inevitably created in the center of the device.

The mechanism is driven by an electric motor. The paddle wheel is not set completely in the center to allow forcing and pushing gas through the system. The disadvantage of the system is that the liquid with which the process is carried out (more often it is water) is constantly heated and it has to be changed.

Such a pump is provided with inlets through which water enters and outlets through which gas is discharged.

Mechanisms that function in this way are used in large enterprises, as well as in agriculture, to remove gases with a large amount of suspended matter in the form of dust and sand. For continuous operation, a gas outlet, a constant water supply and a motor cooling system are provided.

The simplest vacuum pump

Since the simplest vacuum pump may be needed at any time, you can make it in the most elementary way from plastic bottles of different diameters. It will be a primitive vacuum pump, a home-made manual mechanism.

For manufacturing you will need:

- Two bottles that easily fit together. One of them will be a piston, so you need to pick up bottles that are not too different in diameter, otherwise you will have to make a serious layer of sealant on the inside.

- Hose from a bicycle pump.

For a larger bottle, cut off the top. We make holes in the bottom of a smaller bottle. We insert the bottles into each other, on the inner bottle we make a sealant from adhesive tape, if necessary. Screw the bicycle pump hose into a large bottle, in the opposite direction. So he will pump air when the piston moves from a small bottle.

The main types of vacuum pumps:

- Water ring devices - work is ensured by immersion in a fluid of a mechanism, which, rotating, creates a vacuum in the center of the chamber of the blade mechanism.

- Rotary vane Vacuum devices are usually two-chamber, and operate on the principle of pumping gases from one chamber to another, which is ensured by the operation of the rotor mechanism.

- Diaphragm piston vacuum apparatuses - vacuum injection is ensured by the operation of the piston system; during compression, the gas is discharged outside the chamber through the valve, which ensures a decrease in pressure in the chamber and the arrival of a new portion. Such piston pumps are among the most silent and versatile.

Vacuum pump in the home

Vacuum pumps are designed to create a rarefied space in separate volumes. It can be either plastic bags in which you are going to store food or warm clothes, or Split systems of air conditioners. The system of vacuum braking in vehicles significantly increases the life of the vehicle.

At first glance, it seems that there is no urgent need for vacuum systems in everyday life. And indeed it is. However, try to assemble the simplest vacuum pump with your own hands and you will be surprised how many ways to use it.