How to install a drainage pump with a float switch. Drain pump with integrated submersible float. Universal pump gnome.

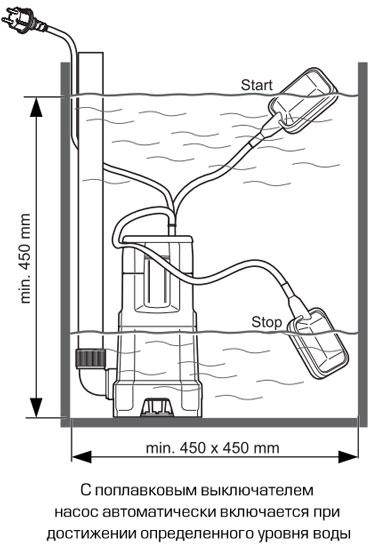

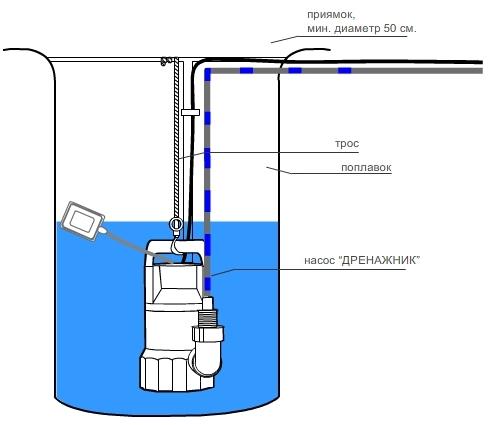

Drainage pumps with a built-in float are used for installation in tanks, storage tanks, tanks, wells and other structures. Several floats can be installed in one tank with different functions: pump control, liquid overflow sensor, emergency level sensor.

When using them, protection of pumping equipment in the “dry run” mode is provided, and protection against overflow when filling the tank. How to use the device with your own hands suggests introducing this article.

Purpose and principle of operation of drainage pumps

Float-free are needed for use in summer cottages and household plots, where they relieve their owners of many unpleasant problems. The main task of the devices is to ensure the discharge of rainwater, wastewater, pump out melt water from basements, cellars, wells, ditches, pits.

A drainless floatless pump is used when pumping water from the pool, foundation pit, artificial pond. Special modifications of drainage units allow pumping out contaminated water.

For a minute, a drainage pump, with average technical characteristics, can pump out about 180 liters of water. The power of the device decreases with the immersion and the range of the pumping place.

Tip: Most drain pumps for pumping hot water not intended.

There are two pipes in the design of the unit:

- Entrance through which water is sucked from a filled sewage pit.

- The output, through it, the liquid is discharged outside the site. Fluid must not enter the engine.

This may cause the unit to malfunction. In this case, the pump must pump the drains faster than their level can rise in the pit.

Tip: Pumps are connected to the sewer system through nozzles. Therefore, when installing a drainage pump, it is necessary to know the diameter of the sewer pipe with an accuracy of one millimeter.

The main advantage that a floatless drainage pump has is mobility. The equipment can freely move to any place where necessary. Repair, in case of breakage, can be done easily and quickly.

Features of drainage pumps with floats

To protect the pumping equipment, special float devices are used. The price of such devices is relatively small compared to the advantages that they have.

There are two types of float switches:

- Lungs, used mainly in water supply and water discharge systems.

- Heavy, used for drainage, sewer, rainwater.

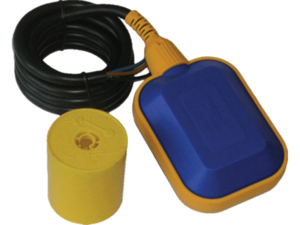

A float switch is a floating device in a plastic box.

Inside it are:

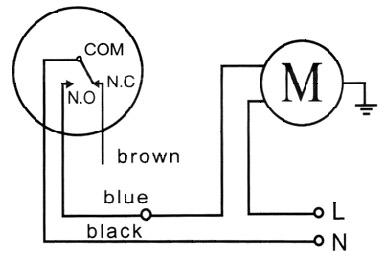

- The switch is electric. From it comes a cable with three wires of different colors: one wire is common and two from the normally open and normally closed contacts of the switch.

- A steel ball that closes or opens the contacts of the circuit when the position of the float changes.

When the float is at the bottom, the circuit closes with a common wire and is normally open. If the float is at the top, the contacts of the wires of the common and normally closed are closed.

A wire that is not currently used in the circuit must be insulated.

Tip: When purchasing a float, you should pay attention that the plastic box must be hermetically closed, and the cable was moisture resistant.

The cable outlet is sealed with a mechanical seal during manufacture. If necessary, remove mechanical stresses in the cable, a special device is used, which is included in the delivery package of the float.

The cavity where the cable enters is insulated and filled with polymer resin, which prevents moisture from entering. The material for the manufacture of the housing has good heat resistance, and thermoplastic rubber is used for the cable sheath, which makes the float switch resistant to alcohols that are harmful in the chemical composition of uric acid, liquid oils, gasoline and other substances.

There are no pores on the surface of the plastic casing, which eliminates the possibility of all kinds of contaminants sticking to it. Sand, paper and other solid inclusions freely slide off it, without exerting any influence on the buoyancy of the float switch.

How to install the device

The installation procedure for float switches is as follows:

- The current drawn by the pump is checked. It must be less than the maximum allowed, which indicates the instruction manual for the float.

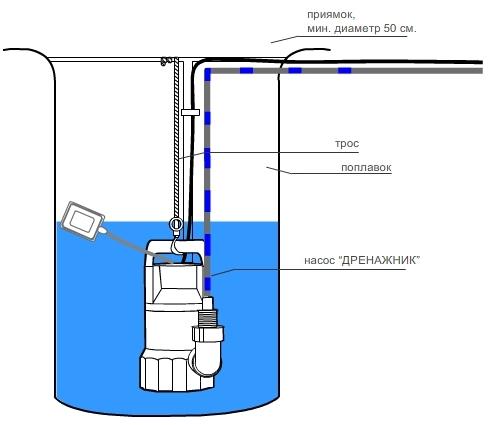

The easiest and fastest way is to install in a tank.

In this case, a float with a cable and a special weight, included in the kit, are used:

- The weight is put on the cable and the size of the freewheel of the float is determined empirically.

- The weight is latched onto the cable.

- The cable itself is securely attached to the outside of the container.

- A float switch is connected to the pump.

Tip: The installation of the float switch on the supply cable can only be carried out when there is no danger that the float switch can catch or hang inside the tank and only one float switch should be in it.

When mounting several float switches in the tank, they must be mounted on a special rod. Its role is usually played by a piece of plastic pipe placed and securely fixed in the container. After that, floats are attached to the pipe.

To do this, they:

- Expose.

- Regulate.

- Spread along the length of the rod so that they could not interfere with each other correctly perform their intended functions.

- From the float switches, the running cables are fixed with clamps to the rod, as seen in the photo.

- The number of float switches is selected depending on the number of pumps or on the number of protective devices, their types and control panels used.

- There are times when for the reliable operation of these devices it is necessary to use several rods.

The number and where to mount the float switches is determined individually by place during installation or according to the project.

What is the principle of a float switch?

Several uses for float switches. Water system when filling and emptying the tank tank.

In this case:

- The pump for filling the tank will turn off the float switch when floating, when the tank to be filled is full, and turn it on when lowering to the bottom if the tank is empty.

- The device will turn on the water supply when it is on the surface, the tank will be full, and turn off the station, when lowering to the bottom, in this case the tank will be empty.

- The device will give a command to close the valve or valve with a servomotor, when raised to the surface, the tank will fill up and open the valve or heck when lowered to the bottom, the tank will empty.

- The device will give a command to the dispatcher to the point or to the operator, when raised to the surface, the tank is full, and it will signal a lack of water, when lowered to the bottom, the tank will become empty.

Sewer system:

- The device will turn on the fecal pump, if it floats on the surface, the tank is full, and turn off the pump, when lowered to the bottom, the tank will empty.

Two pumps can be connected to one float: one pump will fill the tank if the float is in the lower position, at this time the second pump does not work, and in the upper position of the device the second pump works, pumping the tank, and the tank filling the tank, at this time work will not.

Such a scheme for the use of a float switch is not very effective; there may be interruptions in the delivery of liquid for a while when filling the tank. The video in this article shows how the drainage pump with a float works.

Operation, repair and maintenance of float switches

Subject to all operating conditions, float switches operate for a long time without repair. If the device is used in a plumbing system or when draining water, then it does not need periodic maintenance.

If the float switch will operate in sewer pits, it is necessary to rinse at least once a month from pollution of the float and pump with a jet of water under pressure, which will prevent sticking or sticking of the float to the drain pump or to the pipe. If the contacts burn out, moisture gets inside the float, the cable insulation is damaged, the float switch cannot be repaired, but it needs to be replaced.

To prevent the “dryness” of the pumps, there are many different control techniques. The use of a float switch for water level is one of the most affordable and effective ways to protect the equipment from possible breakdowns. The indisputable advantage of its use is the possibility of simultaneous use in two forms - as an executive element of equipment control and in the role of a controller that determines the water level.

The field of activity of water level switches is very wide, for example, in systems responsible for water supply and sanitation. Switch floats serve wells, storage tanks, are used in all kinds of containers. They are used in sewage systems.

Up to several switches can be located in one tank, each of which has its own function: one controls the auxiliary pump, the other controls the main one, the third acts as an emergency water level sensor, and the fourth monitors the overflow. In any case, the number of floats is determined by the number of connected pumps, as well as the need for protective devices in the system.

Fasteners of several floats are made on a special mounting rod. In its role, it is possible to successfully use a pipe made of plastic that is securely fixed in the tank. Switch floats are fixed on the rod at a distance from each other so as not to interfere with the work of a neighbor. The cable fastening of each switch is carried out by fastening with clamps. There are situations when the necessity dictates the use of several rods for fastening floats.

Taking into account the working conditions and project features, the number of switch floats needed to organize the work of a particular system is determined.

There are two types of float switches:

- Easy - for a system that controls water supply or water discharge;

- Heavy - designed to control drainage or fecal pumps.

Float switch in action

Before connecting the newly purchased float switch to the pump, it is advisable to verify the compatibility of their technical characteristics.

An elementary way to configure the operation of the switch for electric pumps is inside the water tank.

Sequential wiring diagram for a float switch:

- Attaching a special sinker (from the kit) to the float cable.

- At the edge of the tank, the cable is securely fixed.

- The amplitude of the freewheel of the float switch is adjustable to adjust the highest and lowest levels, upon reaching which the float switch will work.

- The float switch is connected to the pump last.

If there is a danger of the float freezing or preventing its free passage in the tank, the connection cannot be made.

The main functions performed float switch:

- A float connected to a pump that performs the task of filling the tank will shut off when it emerges and connect when the bottom mark is reached.

- For an automatic station: switching on when the upper level of the liquid level is reached and turning off on the lower (reaching the bottom of the tank).

- Valves or gate valves with a servo actuator: the switch will give a signal to close when it is in the upper position (full capacity) and it will open the way to water when it reaches the lower position.

- Dispatch point: monitoring excess and lack of water.

It is possible to bring two pumping devices to one float: the function of the first pump is to fill the tank at the time of the bottom location of the float, the mission of the second is to pump water at the time of the top location. The scheme is effective only in case of uninterrupted water supply to the tank.

Some options for connecting circuit breakers to prevent pumps from "dry running".

The role of signaling devices in drainage pumps

Drainage pump with a float switch is widely used in industry and in everyday life. The scope of its use is cleaning wells, removing dirty liquid, etc. In the drainage pump, the float is endowed with the function to turn the drive on and off automatically. The switch is lowered into wastewater by means of an elongated cable together with a pipe for fluid intake.

The vertical type drainage pump kit includes a vertical float switch with the function of pumping liquid from an enclosed space. Such a drainage pump can, for example, drain idle pipelines.

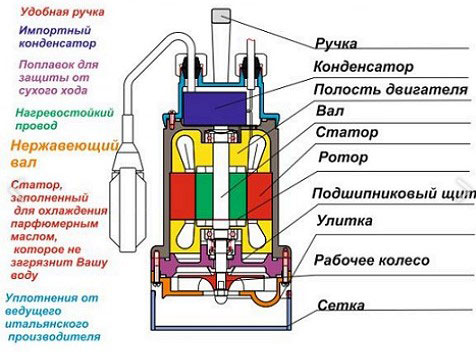

Design and principle of operation of the circuit breaker

Float Design: an electro-switch and a ball of steel placed in the inner cavity of the plastic case.

Cable length varies from 3 to 10 m.

When the float switch reaches the upper mark, the switch contacts will close, ensuring that the pump is turned on. Once the float goes down to the bottom mark, a steel ball acts on the switch lever, changing its location. The circuit opens and the system turns off.

Connection diagram for float switch: a cable with three wires is connected to the switch. They differ in color, often are black, blue and brown. The common wire is marked in black.

In the upper position of the float switch, the contacts of the common wire and normally closed, marked in brown, are closed. At the minimum mark, the circuit closes with the participation of a common wire and normally open, indicated in blue.

The insulation of the wire that is not currently used in the circuit must be very reliable.

It is understood that in an aqueous environment, the cable must have sufficient moisture resistance, and the plastic casing must be leakproof. The cable outlet is equipped to relieve mechanical stress and is securely sealed. The polymer resin filling the cavity of the cable entries eliminates the ingress of moisture inside.

And the last word in favor of the float switch is the price, which usually varies from 300 to 500 rubles. The combination of a pleasant price and reliability makes the purchase of a float switch the best option for protecting against unwanted breakdowns of expensive equipment, such as domestic and industrial pumps.

It’s hard to find an alternative to a private drainage pump. Without it, it will become problematic to pump out a basement flooded with groundwater, drain the pool, free flooded drainage collectors. However, the technique is not eternal, so the device may break, and before buying a new one it will be necessary to somehow deal with the solution of problems. In this situation, repair of the drainage pump with or without a float will help.

Features of the design of floating devices

The approximate speed of pumping water with a drainer is about 180 liters per minute. Operating power depends on such factors:

- the conditions in which it is operated;

- remoteness from a water source;

- degree of immersion in the liquid;

- contamination of the pumped liquid.

It should be borne in mind that repair of drainage pumps may be necessary after pumping out too hot water, because not all models are designed to work in extreme conditions.

The construction of drainage equipment

The modern drainage pump without a float in the design has a pair of nozzles:

- input, in contact with the suction surface of the liquid from the tank;

- water outlet to the owner-defined area.

During the process, no drops of liquid should fall into the area of \u200b\u200bthe electric motor, as this can lead to its failure. In order not to bring to the repair of fecal pumps or other drainage machines, it is worth making sure that pumping takes place faster than the inflow into the tank.

It is possible to connect to sewer systems by means of branch pipes, and it is very necessary to establish them very clearly in relation to the diameters of sewer pipes, practically eliminating the possible appearance of gaps.

The main advantage of a drainage pump without a float is its high mobility. At the same time, repair of drainage pumps of this type is easier than their counterparts.

Float apparatus design

Float schemes are more secure. The relatively low cost of these units is also a positive factor. The float element responsible for switching off is usually located in a separate plastic box.

There are two types of such elements:

- light, relevant for water drainage and in the water supply;

- heavy, in demand in rain sewage and sewage.

When choosing a float, it is necessary to check its maximum tightness and high-quality insulation of the supply cable.

Common Problems

If the fecal pump does not work or the repair of Jileks pumps is required, then the following cases may be possible causes of breakdowns:

- the motor winding burned out, while a characteristic odor may appear;

- the float may be stuck below the horizontal start;

- failure of the starting capacitor;

- the impeller is wedged due to the ingress of foreign mechanical particles.

Do-it-yourself repair of the Dzhileks pump is also necessary if a rumble is heard from him, but water is not pumped:

- stem breakage;

- the service valve is damaged;

- the mounting of the shock absorber is loose;

- the power cable is damaged.

This list includes the most popular causes of breakdowns, but individual situations occur or several emergency situations occur simultaneously.

Recovery work

Do-it-yourself repair of a Dzhileks pump or other drainage equipment is not always possible without special tools. In some cases, even they will not help, since an expensive replacement of parts or entire assemblies will be required.

The most popular types of repairs are releasing a float or removing particles blocking the rotation of fiber. You can also fix the shock absorber yourself or replace the cable. The shock absorber is fixed in a disassembled case. The thread on the mounting bolts is tightened, and the upper nuts must be checked.

It takes some time to repair the cable, and replacing a burnt capacitor will not be possible to do on all models with your own hands.

When the stem breaks, this part is practically not subject to recovery. Will have to purchase new equipment. Valve repair also applies to unprofitable operations.

If you have knowledge of electrical engineering and there is a sufficient amount of wire to rewind the electric motor, then this procedure is carried out at home. Some repair shops offer, for a relatively small fee, this part of the repair of Gileks pumps.

VIDEO: Dismantling and repairing the drainer

Repair a damaged cable

Not in all situations, cable damage may be noticed. The frayed winding will be visible from the outside, but it is problematic to determine the gap in the inner part without external signs.

It is important to determine the point at which the breakdown occurred. One of the popular places is the bend near the plug or the place where the cable enters the pump housing. In this situation, experienced professionals use the manual verification method.

To carry out restoration work, it will be necessary to disassemble the case, but unpleasant surprises associated with the use of exotic curly screwdrivers can be expected here. Often this is used to protect the product from unprofessional interference.

When dismantling the cover, it is necessary to gently sway, without making sharp jerks, so as not to damage the winding. The cavity contains a tensioner. It is usually dismantled by unscrewing 3 or 4 bolts.

The cable must be removed and cut higher from the cliff, after which it will be necessary to return it back. However, this operation is not as simple as it seems at first glance. The wire swollen from the water will increase in diameter and will not return to the hole or groove. A small amount of engine oil will come to the rescue, facilitating installation.

The coupling can not be removed, as this can cause damage to the part.

The cable is installed in its place, while the tensioner returns and reliable insulation is ensured. During the installation of the cover in its place, it is necessary to trace a clear coincidence of the fixing grooves on the housing to ensure maximum tightness.

VIDEO: Why the drainer does not start

Why the working pump does not pump

Very often, the equipment begins to fail not for any specific reason, but, for example, during critical voltage drops in the mains. If a pump breakdown is observed, it is advisable to check the voltage. Normally it should be 220-240V. If this indicator is correct, then it is already possible to solve the issue of repair.

In order to avoid problems with the winding and in general with the operation of the equipment, it is necessary to install a voltage stabilizer that aligns the plug during operation and all the equipment works correctly.

Dive chart

Also, visually a whole and efficient pump may not pump water for the following reasons:

- air has accumulated in the intake;

- there is not enough water for operation - you need to lower the hose deeper or the pump itself, if it is a submersible;

- the water intake is not submerged in water;

- if a so-called "Frog" is an idle blocker, it can jam and de-energize equipment.

The above problems can be fixed very easily - it is enough to either completely submerge the water intake part in water or tilt it so that all the air comes out or simply unhook the stuck “frog”. In general, it should be noted that all problems must be fixed in a timely manner and professionals should be entrusted with this work.

VIDEO: Repair the drain pump

To ensure convenient control of the pumps, there are a large number of different devices, among which a float is widely used. Among the features of this device, it should be noted that it can simultaneously perform the function of a water level sensor and at the same time an actuator for controlling the pump. The place of their placement are storage tanks, tanks, tanks, as well as wells, etc.

The space of one such tank is enough to accommodate several floats, and they can solve various problems:

- Monitor the operation of the main pump;

- Ensure the efficient operation of the auxiliary pump;

- Act as an emergency level sensor;

- Used as overflow sensor.

Using similar devices to control the water level, which are used in these systems, it is possible to protect the pumping unit from switching to the “dry running” mode. Also, in the case of filling different tanks, this element allows you to protect them from overflow.

Can highlight several types of floats for pumps:

- lungs;

- heavy.

The former are widespread in water supply and sanitation systems. The latter are mostly used as part of drainage, fecal and rainwater. In stores, these devices are offered with cable lengths of 2, 3, 5, and 10 meters.

Device and construction

An element such as a float switch for monitoring the water level has floating plastic case. It contains an electric switch and a lever that allows you to translate the contacts of the switch. Also included is a steel ball, which, in case of a change in the position of the float, adjusts the position of the lever itself. A cable consisting of three wires is connected to the switch: the first is common, and the rest are connected to the normally closed and normally open contact of the switch.

An element such as a float switch for monitoring the water level has floating plastic case. It contains an electric switch and a lever that allows you to translate the contacts of the switch. Also included is a steel ball, which, in case of a change in the position of the float, adjusts the position of the lever itself. A cable consisting of three wires is connected to the switch: the first is common, and the rest are connected to the normally closed and normally open contact of the switch.

Circuit short circuit provide black and blue wires at a time when the heat is in the lower position. In the case of its transfer to the upper position, the black and brown wires will already act as closing contacts. A prerequisite here is the insulation of the wire, which does not provide connection to the device. It is important to ensure that the lead-in cable has moisture-proof properties, while the design of the plastic box must be leakproof. A mechanical seal is used to seal the cable outlet, and it also has a special device that allows you to remove mechanical stresses in the cable.

Inside the insulated cavity of the cable entry is located polymer resinwhich protects against ingress of water. The chemical properties and heat resistance of the cable body and sheath, which are made using thermoplastic rubber, are associated with the ability of the float switch to perfectly tolerate interaction with alcohols, uric acid, fecal water, gasoline and other aggressive substances.

Due to the absence of pores on the surface of the plastic housings, no contamination appears on it. At the same time, this feature ensures the sliding of sand, paper and other solids, against which the float switch retains its floating properties.

Sensor Specifications to control the water level:

- Mains voltage, V - 220 ± 10%;

- Maximum switched current, A:

- 8A - for reactive load (pumps, fans, compressors, etc.);

- 10A - for active load (starters, switches, electric heating elements, lamps, etc.);

- Operating temperature range: 0-60 ° C;

- Protection: IP 68.

Benefits

Among all the advantages that a float switch has to control the water level, first of all, it should be highlighted that it is capable of perform the function of a conventional sensor to determine the water level in tanks. Moreover, he successfully performs this task, even despite the fact that for what purpose the capacity is used and how much it has volume. At the same time, this water level control device is able to help make the operation of pumping equipment more convenient. With the help of such a device, the control of the functions of industrial, domestic water supply systems is simplified.

Among all the advantages that a float switch has to control the water level, first of all, it should be highlighted that it is capable of perform the function of a conventional sensor to determine the water level in tanks. Moreover, he successfully performs this task, even despite the fact that for what purpose the capacity is used and how much it has volume. At the same time, this water level control device is able to help make the operation of pumping equipment more convenient. With the help of such a device, the control of the functions of industrial, domestic water supply systems is simplified.

In some cases, it can be used to successfully drain fluid. Also, a float switch to control the water level can be part of the equipment during the construction of sewer communications. Simplicity of work and high efficiency of its application and provided the float switch wide distribution in a wide variety of systems where the task of controlling water arises.

It is worth noting that the ability to provide reliable protection for pumping systems during dry-running operation is not the only positive qualities of such devices. At the same time, with their help, it is possible to avoid a situation when water overflow occurs in containers.

Mounting

To install float switches, you can use one of several methods. Before installing this device, make sure that the current rating used to operate the pump is less than the maximum allowable current value given in technical specifications on this type of float. Among the known methods of mounting a float switch for monitoring the water level, the easiest to implement is placement in the tankproviding for the use of a float with a cable and a special sinker, which is attached to this device.

To install float switches, you can use one of several methods. Before installing this device, make sure that the current rating used to operate the pump is less than the maximum allowable current value given in technical specifications on this type of float. Among the known methods of mounting a float switch for monitoring the water level, the easiest to implement is placement in the tankproviding for the use of a float with a cable and a special sinker, which is attached to this device.

With this installation option, the sinker must be fixed on the cable, and then empirically calculate the length of the free-wheeling shoulder of the float. Using the latch, you need to fasten the weight on the cable. After that, the cable itself must already be firmly fixed on the outside of the tank. Next, they are already moving on to connecting the float switch to the pump. After that, the device can be used for its intended purpose.

The option to install a float for pumps, involving the use of a supply cable, can only be used in situations where there is no risk of hooks or freezes the main device in the tank itself and when only one float is placed in it.

In some situations, it may be decided to install several floats at once to control the water level. In this case, their installation is carried out on a special rod. As the latter, fragments of a plastic pipe are most often used, which must be firmly fixed in the tank. After that, floats are installed on the pipe, and they must be correctly set, adjusted and distributed along the length of the rod so that they do not create difficulties for each other for normal operation.

The cables that go from the float switches to the rod are brought using clamps. When choosing the number of float switches, you should pay attention to the number of pumps or the type and number of protective devices and control panels used. In some situations, the problem of ensuring reliable operation of float switches can be solved by the use of several rods.

When determining the installation scheme of float switches, their number and location, it is necessary each time to take into account the features of their installation location or to focus on the project.

The principle of operation of the float for pumps

Devices such as float switches can provide various schemes for their use, and this also affects their principle of operation.

Water supply system, filling and emptying the tank tank

![]() With this scheme of operation, at the time of ascent, the float de-energizes the pump, which supplies water to the tank. Power on signal only when it reaches the bottom. This situation occurs only with an empty tank.

With this scheme of operation, at the time of ascent, the float de-energizes the pump, which supplies water to the tank. Power on signal only when it reaches the bottom. This situation occurs only with an empty tank.

The float gives a signal to turn on the automatic water supply station when it is on the surface. Shutting down the station can only happen when the float sinks to the bottom with an empty tank.

On the float side, a signal was received to close the valve or valve with a servo actuator at the time of its rise to the surface. The opening of a valve or valve will only happen when it sinks to the bottom with an empty tank.

The work of the float can only be in the control room alert or the operator at the time of its rise to the surface, which will correspond to the filling of the tank. Information about the lack of water will arrive at the moment when the float reaches the bottom.

Sewage system

The fecal pumping equipment will be switched on by the float only at the moment the main control device is raised up. The pump unit is switched on when the control device is immersed to the bottom.

One float can simultaneously serve two pumping units: the first unit can supply water to the tank, provided that the float is in the lower position. At this moment, the other pump is idle. When the float is in the upper position, the second pump is turned on, the task of which is to pump water from the tank. At this time, the pump, which supplies water to the tank, is in an inactive state. Despite its simplicity, the above scheme for the use of a float switch is not effective enough, since this does not exclude difficulties with the regular delivery of water at those moments when the tank is filled.

Operation, maintenance and repair

It is possible to ensure long-term operation of floats for pumps only if the rules for their use are not violated. In a situation where the float switch is part of the water supply and sanitation system, you can not waste time and effort on its maintenance. If this device controls the operation of fecal or sewer pits, it is recommended that at least once a month float cleaning and the pump from pollution, using a stream of water supplied under pressure.

It is possible to ensure long-term operation of floats for pumps only if the rules for their use are not violated. In a situation where the float switch is part of the water supply and sanitation system, you can not waste time and effort on its maintenance. If this device controls the operation of fecal or sewer pits, it is recommended that at least once a month float cleaning and the pump from pollution, using a stream of water supplied under pressure.

This procedure will prevent sticking or sticking of the float to the pump or pressure pipe. The float switch, which due to certain circumstances is not able to perform its main task, is not repairable, therefore, in such situations it is replaced. Specialists of service centers should carry out this work.

Conclusion

In situations where there is a need to ensure the supply of drinking water to the house or the removal of polluted effluents, it is necessary to use in combination with pumping equipment and special devices. Among them, a float switch is quite effective. The benefit of its use is that it controls the amount of liquid in the tank, and, focusing on this, determines the operating mode of the pump unit.

This device allows you to avoid the transition of the pump to the "dry run", which positively affects its service life. In addition to this, a considerable amount of energy is saved, since the float switch allows the pump to be activated only if necessary.

Submersible drainage pumps pump out both clean and dirty water. Therefore, during the pumping process, the device controls the minimum liquid level on its own using a float sensor. Indeed, only this unit can protect the unit from overheating or damage to the pump part due to dry running, since when the level drops below the critical level, the “fallen” float shuts down the pump motor.

That is why units equipped with float sensors will last longer than pumps without this unit. Indeed, overheating and dry running destroy both the engine compartment and the working chamber of pressure equipment.

And in this article we will consider the list of the most popular drainage pumps equipped with a float sensor. Perhaps you can find in this list the optimal model of drainage equipment suitable for domestic use (garden irrigation, pumping wells and basements, draining pools or puddles, and so on).

In this list you will find both expensive European models, and Chinese or domestic equipment, available to a wider circle of customers. But all these pumps have one thing in common - they are in steady demand, both for the end user and for drainage system builders. And this list includes the following samples of drainage equipment:

Italian quality - Pedrollo TOP

The Italian brand Pedrollo specializes in the manufacture of pressure equipment and components for pumping stations. In the drainage segment, the most famous series of this brand is the TOP line, which includes units with a capacity of 10 to 25 thousand liters per hour.

|

|

In addition, pumps from this series pump water both from standard 3-5 meters, and from a more significant depth - up to 10 meters. And some Pedrollo models from the TOP series can even be placed in a narrow casing, with a diameter of 220-250 millimeters. Moreover, the filter at the bottom of the pump passes only medium-sized particles with a diameter of up to 10 millimeters. Therefore, this series is used for pumping light or "gray" drains.

Of course, such equipment needs a sensitive float valve and Pedrollo prudently manufactures its own pumped liquid level control unit.

And thanks to this device, the pumps from Pedrollo are famous for their longevity, supported, among other things, by the other technological know-how of this manufacturer (ceramic seals, the special shape of the impeller, shafts and filters made of stainless steel, etc.).

The cost of pumps from the TOP series ranges from 6-7 to 13-14 thousand rubles.

Russian-Chinese breakthrough - Dzhileks "Drainage"

The Dzhilazhnik series of the Jileks brand was developed in Russia, but is produced by Chinese partners. Moreover, the product quality control system in this Russian-Chinese company is built according to the best European standards.

As a result, the series is famous for its powerful pumpsoperating in harsh conditions (the unit pumps liquid with the inclusion of solid particles with a diameter of up to 35 millimeters) for a sufficiently long period (up to 10-15 years).

And the best guarantee of such longevity is a float valve designed specifically for this series. With the help of this unit, the pump is protected from overheating and is switched off in case of contact between the working chamber and air. “Drainer” also has an internal heat exchange chamber, which allows you to turn on the pump even if it is not completely immersed in the pumped medium.

The performance of specific models from the Drainage series depends on the power of the motor and the dimensions of the working chamber of the pump. For example, an 880-watt 200 / 10F Drainage pump shakes up to 12 thousand liters an hour, lifting liquid or suspension from a depth of up to 8 meters. However, in this series there are also less productive units operating from a 200-watt motor with a capacity of up to 9,000 liters per hour.

The average cost of pumps from the Drainage series is 4-5 thousand rubles, which, considering the high performance, is quite good.

Hungarian classics - Grundfos Unilift

The Hungarian company Grundfos produces in the Unilift series high-performance pumps that can work with any environment. After all, the cases of these devices are made of stainless steel, and the special design of the working chamber makes it possible to turn on the pump not only in the classic "vertical" position - Grundfos Unilift is launched on an inclined plane, and even "lying" in a horizontal position.

Therefore, on the basis of Unilift it is possible to assemble both a portable and a stationary pumping system groundwater or artificial tanks (including sewer sumps or drainage wells).

After all, these pumps raise with a 10-meter head up to 14,000 liters of effluent per hour, and their electric motor consumes no more than 400 watts.

That is why Unilift are quite expensive - from 14-15 thousand rubles, depending on the model.

Ukrainian assembly - GNOM pump

A well-known brand from the Soviet era from a neighboring country received a batch of fresh ideas from a modern manufacturer - the company Polesieelectromash. And now the GNOM pump is packed in a cast-iron case and equipped with removable filters that can be cleaned even in the field.

Well, thanks to the “Soviet” hardening, this unit can be used not only in almost “greenhouse” conditions, pumping water from a pool or storm well, but also in hardcore mode - when pumping liquid from a construction pit, when pumping wells, and so on.

And even in these difficult conditions, the “Gnome” will not let its user down, providing a rise in water with a 16-meter head and a productivity of 12-16 thousand liters / hour.

And for all this you have to pay only 5,000 rubles!

European choice - Grundfos KP

Another product of the Hungarian company Grundfos - a series of drainage pumps KP - is focused on semi-professional use.

After all, Grundfos KP are quite expensive (from 13 thousand rubles), but I also work “for three,” pumping about 14,000 liters / hour with a 9-meter head.

And the Kyrgyz Republic has a durable stainless steel case and its own heat protection system, thanks to which the pump can be installed anywhere: even in a narrow well, even in a foundation pit. And no need to maintain the mechanical part! Yes, this is not a pump, but just a gift!

Affordable Italy - Ergus Drenagio 400 F

Italian companies offer the global market not only expensive, but also low-cost equipment. At the same time, the level of quality and assembly remains virtually unchanged.

And a good example of such an inexpensive and high-quality pump is the Ergus Drenagio 400 F model - a centrifugal type drainage pump equipped with a float sensor for monitoring the level of liquid in a drained area.

This unit costs only 2.5-3 thousand rubles, but this did not affect its performance. The 400 F is capable of pumping cock with 35 mm solids, delivering up to 7,500 liters of fluid per hour from a 5-meter depth.

And the low price is explained by the use of a low-power engine (400 watts) and affordable structural material in the design - almost all parts of this pump are made of structural polymers, which does not prevent it from competing with more durable devices, provided that the unit body is carefully handled.

Chinese pump - Herz WRS 40 / 11-180

It is very powerful (power consumption - 1.5 kW) and a heavy unit (weight - 31 kilograms). But the performance of this device justifies everything. After all, Herz WRS 40 / 11-180 pumps from a 10-meter depth of almost 20,000 liters per hour (330 liters / minute), and the pressure of this unit is 23 meters.

Moreover, the Herz WRS series is focused on working with fecal waters and suspensions, and in the lower part of these units a special shredder is installed, crushing unnecessarily dimensional fibers.

And taking into account all these design features, the price of the WRS 40 / 11-180 model - 14 thousand rubles - looks quite justified.

German legend - Karcher SDP 5000

This unit is the youngest model of the well-known series of submersible drainage pumps pumping dirty water. Moreover, the entire "household" Karcher SDP series is famous for its high quality components and accurate assembly. Indeed, in the design of such pumps there are parts from professional equipment of this company.

The Karcher SDP 5000 model is designed for pumping wastewater with a solids content of "caliber" of 5-10 millimeters. The pressure of this model is 6 meters and the immersion depth is 3-5 meters. The performance of the SDP 5000 is moderate - the unit pumps about 80 liters of effluent per minute, which guarantees minimal energy costs - this pump consumes no more than 300 watts.

The float sensor for this model is “proprietary” - it was developed by Karcher engineers. And in this case, it guarantees timely shutdown and inclusion of the unit. But for older models from the Karcher SDP series, this sensor is connected to an intelligent control system that automates the operation of drainage equipment.

The cost of the SDP 5000 model ranges from 3 to 4 thousand rubles.