How to reduce pressure at the pumping station. Water pressure switch for pump: types, installation, adjustment

The pressure switch is a key element in the automation of the pump or pump station, it gives a signal to turn the pump on and off. The factory settings may differ depending on the manufacturer and model, but, as a rule, the lower threshold for turning on the pump is set to a pressure of 1.4–1.8 bar, and the shutdown threshold is 2.5–3 bar. But sometimes such settings of the response threshold are insufficient for the normal operation of plumbing fixtures, so adjustment of the water pressure switch for the pump is necessary , to select individual parameters of its inclusion and shutdown.

Design and principle of operation

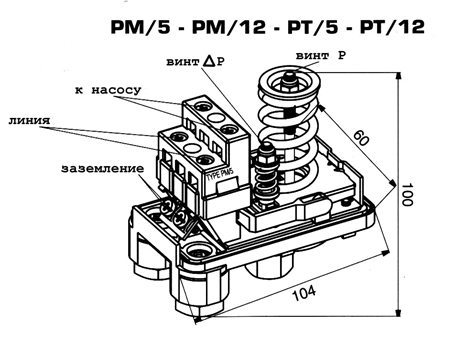

Before setting up the relay, you need to understand the design and principle of its operation. The design of the relay is quite simple and consists of contacts spring-loaded by a plate, which is affected by water pressure.

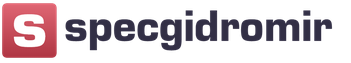

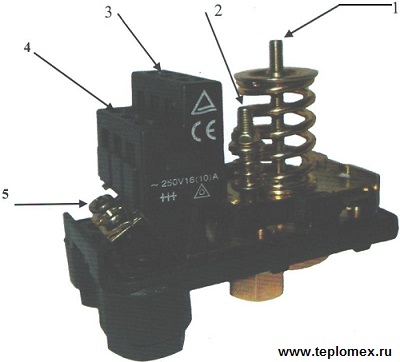

- Body.

- Contact group for connecting the pump.

- Power connection terminals.

- Grounding terminals

- Nut for connecting the relay to the water supply.

- Spring differential pressure adjustment.

- Minimum pressure adjustment spring.

- The assembly where the piston and diaphragm are located.

A metal platform is fixed at one end to a metal base, which can be raised and lowered by a piston. The piston is driven by water pressure. Two springs (6.7) are installed on the platform, a large spring (7) counteracts the force of the piston (water), thereby balancing it. The small spring (7) does not take effect immediately, but after the platform rises to a certain height, and as soon as the platform touches the smaller spring, the forces of both springs begin to counteract and the resistance to the piston increases, from this moment the platform needs to rise quite a bit, so that the contacts open and the pump shuts off. A small joint with a spring is responsible for opening and closing the contacts. As soon as the platform rises above this hinge, the contacts bounce down and the electric circuit opens, as soon as the action of the piston (water) force weakens, the platform goes down and the contacts close.

A large spring is responsible for turning on the pump, that is, for the lower pressure limit, and with the help of a small spring, the moment of shutdown of the pump is regulated, or rather, the difference between switching on and off is set.

Customization

Based on the principle of operation of the relay, its configuration consists in changing the stiffness between the platform, which is affected by water pressure and contacts. The adjustment is carried out by changing the stiffness of the spring, which is either compressed or weakened by the adjusting nuts. Before starting the adjustment, you need to record the pressure gauge during the on and off of the pump. Next, disconnect the relay from the network, and remove the housing cover. Using a wrench, unscrew or tighten the nuts to adjust the necessary parameters:

- if you only need to change the lower switching threshold (increase or decrease), then you need to press or release the nut on the spring (7);

- to increase or decrease the upper limit of shutting down the pump, it is necessary to tighten or unscrew the nut on the spring (6), when tightening, we raise the boundary for shutting off the pump, and when unscrewing, on the contrary, lower it, increasing the difference between switching on and off;

- if you need to change two parameters at once, then first the lower limit is adjusted using the spring (7), and then we set the difference using the spring (6);

All changes must be monitored using a manometer. It is worth considering that by changing the pressure difference, we reduce or increase the duration of the pump, and this will be reflected in the change in pressure in the water supply network. If the pressure difference is small, then the pressure in the network will be “even” without visible differences, but the number of pump starts will increase, which may affect its service life.

Carrying out the adjustment, it must be remembered that the upper pressure should not be higher than the maximum pressure that the pump can create (you can see it in the pump nameplate). The upper pressure should not exceed more than 80% of the maximum allowable pressure for a particular model, and these parameters are indicated in the instructions for the relay. Also, before setting up, you need to check the air pressure in the tank’s pear - it should be 0.2 bar less than the lower threshold for turning on the pump. Another adjustment requirement is the pressure difference between the on and off, it should be in the range of 1–1.5 bar. Changing the parameters, it is impossible to tighten the nuts all the way, this can lead to the fact that the relay ceases to operate at all.

Video

This video shows how to adjust the pressure switch for a pump:

The operation of pumping equipment in the system autonomous water supply regulated by special automation. One of the main parts that control the network parameters is the pressure switch. This device has factory settings defining the lowest and highest limit at which the pump starts. If necessary, change the indicators, the pressure switch of the pump station is adjusted. Such an operation does not require the involvement of specialists, knowing the rules of customization, it can be carried out independently.

Water supply network with relay

How is the pressure switch

Regardless of the manufacturer, the water pressure switch in the water supply system is a compact unit with two springs and electrical contacts. The hydraulic part of the device is a membrane with a piston and two springs of different sizes. Electrical part - contact group, opening / closing network for switching the pump on / off. All structural parts, including the terminal block, are attached to a metal base. The device has several groups of terminals:

- to connect a voltage of 220V;

- for grounding;

- terminals to the pump.

On the back there is a nut connecting to the fitting. From above, the device is covered with a plastic cover, which is fixed to the screw of a larger spring. Products of various plants can be equipped with additional elements, have a characteristic shape and arrangement of nodes, but they all have a similar design. The sensor can be mechanical and electronic. Mechanical devices are more popular due to their low cost.

Relay design

Relay design

Attention. To remove the plastic cover from the device, a screwdriver or wrench is required.

The principle of operation of the relay

The device of the pressure switch of the pumping station does not require human intervention in the process of turning the pump on and off. The principle of its operation is based on a change in the degree of impact on the piston, which is responsible for closing the contacts. A large spring, mounted on a rod with an adjustment nut, counteracts the movement of the diaphragm and piston. When the pressure in the system decreases due to the analysis of water, the contact platform lowers and closes the contacts. The pump turns on and starts pumping fluid.

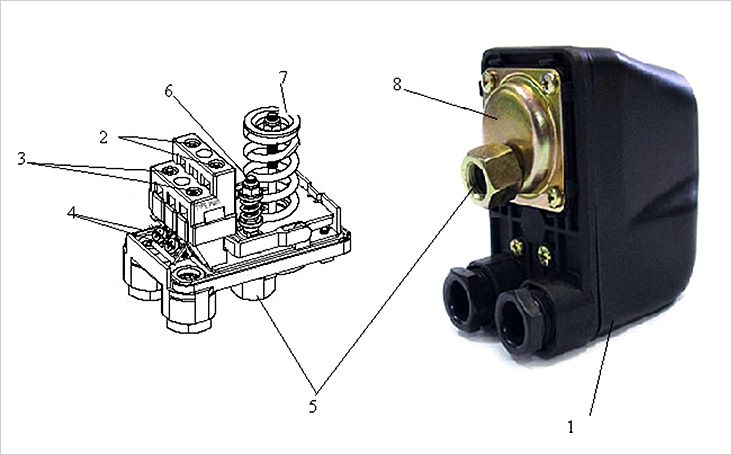

Mechanical pressure controller

Mechanical pressure controller

The flow of water into the accumulator leads to an increase in air pressure on the membrane of the device. The piston, overcoming the action of the spring, begins to displace the contact platform. This process causes the electrical contacts to open. The current is not turned off immediately, but when the platform is withdrawn to a distance determined by the small spring setting. This regulator is responsible for the pressure difference. After complete opening of the contacts, the unit stops the work of pumping water.

Information. A large spring is used to adjust the lower pressure level (on), and a small spring is used to set the upper limit (off).

Pump station preparation

When organizing individual water supply, special equipment is installed - a pumping station. It consists of two parts:

- submersible (surface) pump;

- accumulator.

Read also:

All about the Gileks pumping station: model range, marking, design features and malfunctions

A sealed tank with a rubber membrane installed inside serves to store a supply of water and maintain a stable pressure in the system. Before you start setting up the pressure switch of the pump station with your own hands, you should prepare the tank. The tank consists of a rubber bulb, into which water is pumped, and a chamber filled with air. The amount of air pressure affects the operation of the entire water supply system, so the pump station must be set up.

Preparation of the membrane tank begins with a complete drain of water from the pipeline and the tank itself. For this, the bottom crane of the system is used. Air is pumped into an empty tank, its pressure should be less than the lower limit by 10%. The minimum pressure value is determined depending on the size of the accumulator:

- 20-30 l - 1.4-1.7 bar;

- 50-100 liters - 1.8-1.9 bar.

After determining the pressure in the storage tank, the system is immediately filled with water; the rubber bulb should not be allowed to dry.

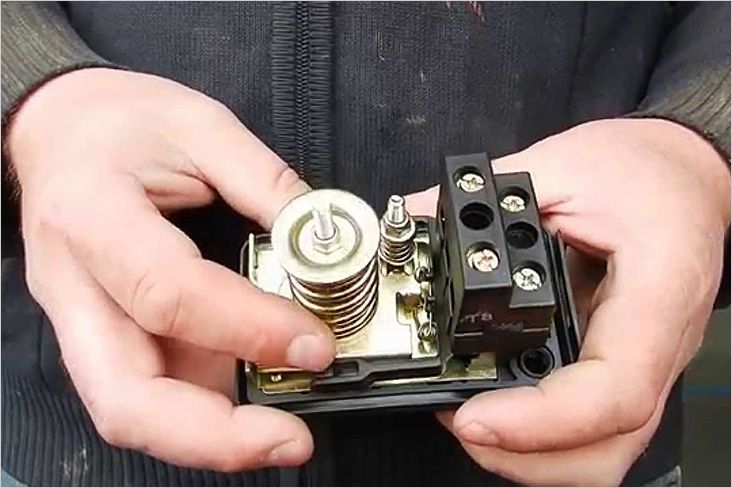

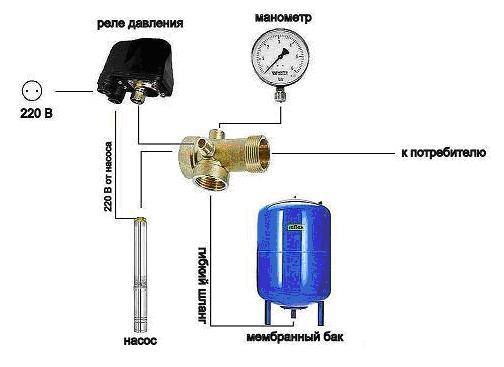

Pump station with accumulator and sensor

Pump station with accumulator and sensor

Attention. Self-checking the pressure in the tank is necessary when assembling equipment from individual parts. Modern models of pumping stations, manufactured in the factory, have ready-made settings specified in the documents.

In order for the tank membrane to last a long time, it is recommended to set the pressure in the reservoir to 0.1-0.2 atm. lower than the minimum level in the system.

Where to install a mechanical controller?

When choosing a location for connecting a pressure switch to a submersible pump, possible turbulence and pressure surges should be avoided. The best option is to install near the accumulator. The operating conditions of the device should be taken into account, in the documents the manufacturer indicates the permissible parameters of temperature and humidity. With a waterproof design of the sensor, you can install it together with the drive in the box. In order for the controller to start functioning, it must be connected to the electric and water supply network.

For a relay, it is desirable to provide a separate electrical line, but this condition is not required. A cable with a cross section of 2.5 mm 2 is laid from the shield. For safety, it is recommended to install a circuit breaker, with parameters corresponding to the characteristics of the pump. Be sure to ground the device.

The terminal block has three groups of contacts: ground, phase and zero from the shield, wire from the pump.

The terminal block has three groups of contacts: ground, phase and zero from the shield, wire from the pump.  Connection is standard - the wire is stripped, inserted into the connector and fixed with a bolt

Connection is standard - the wire is stripped, inserted into the connector and fixed with a bolt

Attention. Connection to the electric network is made according to the inscriptions indicated on the contact group.

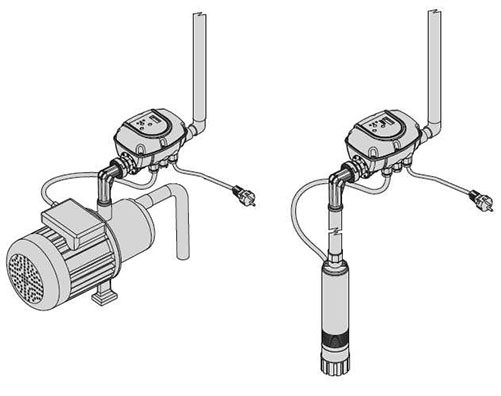

The submersible pump with pressure switch can be connected using a tee or fitting with five outlets. Connection is made through a nut on the back of the device. In the first case, the device is installed directly on the highway. The second option is preferred when a five-part assembly is assembled:

- Submersible or surface pump.

- Pressure gauge.

- Accumulator

- Pressure meter.

- Pipeline.

Relay installation diagram

Relay installation diagram

Tip. All threaded connections of the assembly need to be sealed; for this purpose a sealant or FUM tape is used.

Mandatory elements of the home water supply network are filters. These devices are necessary to clean the liquid from impurities that impair the operation of equipment, including a pressure switch. After connecting the sensor to the water supply and electrical network, it remains only to adjust the pump station with your own hands.

Read also:

Popular models of pumping stations "AL-KO"

Relay setting

The manufacturer provides tuning of pumping stations to average indicators:

- lower level - 1.5-1.8 bar;

- the upper level is 2.4-3 bar.

Lower pressure threshold

If the consumer is not satisfied with such values, then knowing how to adjust the pressure in the pump station, they can be changed. Having dealt with the installation of the correct pressure in the storage tank, proceed to adjust the sensor settings:

- The pump and relay are disconnected from the power supply. All the liquid comes out of the system. The pressure gauge at this point is at zero.

- The plastic cover of the sensor is removed using a screwdriver.

- Turn on the pump and record the pressure gauge at the time of equipment shutdown. This indicator is the upper pressure of the system.

- The faucet opens farthest from the unit. Water gradually drains, the pump turns on again. At this moment, the lower pressure is determined by the pressure gauge. The pressure difference that the equipment is currently configured for is calculated mathematically - by subtracting the results.

Attention. To get the correct settings, you need a reliable pressure gauge, the readings of which can be trusted.

Having the opportunity to evaluate the pressure from the tap, select the necessary setting. Adjustment to increase the pressure of the pumping station is carried out by tightening the nut on a large spring. If the pressure needs to be reduced, the nut loosens. Do not forget that the adjustment work is carried out after disconnecting the device from power.

Attention. Setting is done carefully; the relay is a sensitive device. One turn of the nut changes the pressure by 0.6-0.8 atmospheres.

Upper pressure threshold

To set the optimum pump start frequency, it is necessary to adjust the pressure difference. A small spring is responsible for this parameter. The optimal value of the difference between the upper and lower pressure threshold is 1.4 atm. If it is necessary to increase the upper limit at which the unit is switched off, then the nut on a small spring is twisted clockwise. With a decrease - in the opposite direction.

Setup pattern

Setup pattern

What effect does such adjustment have on the equipment? A figure below the average (1.4 atm.) Will provide an even supply of water, but the unit will often turn on and break quickly. Exceeding the optimum value contributes to the gentle mode of use of the pump, but the water supply will suffer due to noticeable pressure surges. The pressure difference of the pump station is adjusted smoothly and carefully. The result of exposure requires verification. The pattern of actions performed when setting the lower pressure level is repeated:

- All devices are disconnected from the mains.

- Water drains from the system.

- The pumping equipment is turned on and the result of the setting is evaluated. If the performance is unsatisfactory, the procedure is repeated.

Read also:

Well surface pump selection criteria

When making pressure difference settings, there are limitations to consider:

- Relay parameters. You can not set the upper pressure threshold equal to 80% of the maximum rate of the device. Data on the pressure for which the controller is designed are present in the documents. Household models usually withstand up to 5 atm. If the system needs to raise the pressure above this level, you should buy a more powerful relay.

- Pump specifications. Before choosing an adjustment, check the equipment specifications. The unit must be switched off at a pressure of 0.2 atm. below its upper limit. In this case, it will function without overloads.

Features of adjustment "from scratch"

If both relay springs are loose, the automation of the pumping station is adjusted according to the following algorithm:

- The unit is turned on to pump water into the system. The pressure level is controlled by observing the stream from a distant tap. If the pressure is acceptable, then the pressure gauge is recorded, and the pump is turned off.

- Having disconnected the sensor from the mains, open the cover and turn the nut of the large spring until the contacts close.

- The box is closed and the device is plugged in again. The pump is turned on and left to work until the pressure on the pressure gauge reaches the level equal to the previous value plus 1.4 atm.

- The unit and the relay are disconnected from the power supply, then tighten the nut on the smaller spring until the contacts open. The lower and upper threshold settings are completed.

Pressure switch with pressure gauge

Pressure switch with pressure gauge

Using the sensor without a hydraulic accumulator

For some equipment models, a connection diagram for a well pump with a pressure switch without an accumulation tank is used. A special automatic controller starts and stops the unit when the boundary indicators are reached. The electronic unit has the function of protection against "dry running" and ensures the safe operation of the system.

Attention. The disadvantage of this scheme is the lack of a minimum supply of water, which provides a membrane tank.

Electronic pressure switch for surface and submersible pump

Electronic pressure switch for surface and submersible pump

It may need to be adjusted - adjust the on and off pressures. By default, factory settings are set on it, you can specify them in the device passport, usually they are set like this: turning on the pump at a pressure below 1.4-1.8 bar and turning it off at a pressure above 2.5-3 bar.

To adjust the pressure switch, you must first know the desired settings for its operation. They should be determined even at the stage of calculating the water supply system and the choice of pump and accumulator. To configure, you need to remove the relay housing.

Two springs are responsible for the adjustment:

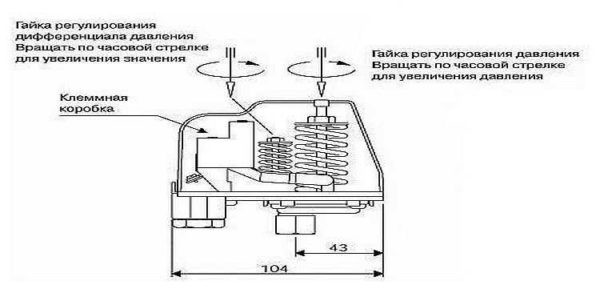

- The large one controls the response pressure and is indicated on the relay itself as P

- The small one controls the difference between on and off pressures and is indicated by ΔP

The regulators are two nuts that specify the compression ratio of each spring: clockwise rotation of the nut (tightening) compresses the spring and increases the value. To increase the switching pressure, you need to tighten the nut of the large spring, and to reduce - loosen it. To increase the difference between the on and off pressures, tighten the nuts of the small spring, and to decrease, loosen it.

To control what pressure is obtained as a result of the adjustment, a pressure gauge is used.

How to set up a pressure switch?

- Open the tap to start water consumption. The pressure gradually drops until the pump starts. The pump start pressure can be recorded using a pressure gauge.

- Close the tap and wait for the pump to turn off. The pressure switch will turn off the pump when the pressure reaches maximum. Using a pressure gauge, you can determine this value.

- If it turns out that the relay pressure is set to the wrong switching pressure, you need to adjust it by turning the nut of the large spring. It is necessary to increase - to twist, it is necessary to reduce - to weaken. At one time, it’s better not to turn the nut more than one turn.

- Repeat steps 1, 2 and 3 until the desired switching pressure is set.

- If it turns out that the shut-off pressure does not match what you want, then adjust it by turning the nut of the small spring. To increase the shut-off pressure, tighten the nut; to decrease, loosen.

- Repeat steps 1,2 and 5 until the desired shut-off pressure is set.

After completing the settings, put the relay case back on.

- A dry running sensor is required in autonomous water supply systems to protect the pump from running without water. Dry running occurs when the pump suction pipe is above the water level. Sensors detect dry running and turn off the pump before it fails.

- The water pressure switch is a water supply automation device that automatically switches the pump on when pressure drops and switches it off when the desired pressure is reached.

- A pressure switch is used to automate the operation of plumbing systems and provides control on and off of the pump. For this, the relay must be connected to the water supply system, to the mains and to the pump. This article will discuss the simplest connection example.

Read also:

Water pressure switch for pump Nowadays, it is universally used for water supply systems of a private house, cottage or other objects where automatic water supply to the points of water intake is needed. Today, a water pressure switch is a necessary attribute for pumping equipment for the area where there is no centralized water supply system: personal plots, country houses, cottages, etc.

Today we will analyze the device and the principle of operation, specifications and settings of the pressure switch, we will consider the differences and their application, as well as the main malfunctions, their causes and repair.

Features of application and price

The water pressure switch is designed for joint use with electric water pumps with a single-phase 220 Volt connection in a water supply system:

- pumping stations for water supply and a hydraulic accumulator;

- centrifugal surface pumps;

— well pumps;

- submersible;

- submersible vibrating pumps like "Kid" or "Trickle."

Pressure switch for pump

As a rule, a pressure switch is already included in the package, and sometimes submersible pumps. In other cases, this device is purchased separately. Connection to the highway is via a five-pin fitting. The relay is available either with an external thread (“male”) or with a nut with a female thread (“female”). The diameter of the thread is usually 1/4 '.

It is worth noting that the price of a water pressure switch directly depends on the manufacturer, for example, Danish Grundfos or Italy Speroni pressure switches - from 1000-2000 rubles, while Chinese can be bought for 200-300 rubles. Russian "Dzhileks" RDM-5 or RD-5 - from 700 rubles. But, if you choose quality, it is better to buy automation under a European brand.

In addition, the pressure switch may have a built-in pressure gauge, or it may be part of the pump automation unit in conjunction with a dry run protection relay. Accordingly, this also affects the price in the direction of its increase.

The device and principle of operation of the water pressure switch in the water supply system

The pressure switch consists of a plastic case, under which a membrane “hides” that controls the operation of a normally closed group of contacts. This membrane is connected to the pressure line of the water supply system.

In the operation of the relay, there are such concepts as the pressure to turn on the pump and the pressure to turn it off. When buying a pressure switch, you must remember that this mechanism has a factory setting of on and off parameters.

The pump turns on when the pressure threshold for turning it on in the water supply system (2.6 atm) is exceeded and turns off when the shutdown pressure indicator (1.3 atm) decreases. As a rule, switching on occurs at 2.6 atm, and switching off when the water pressure in the system drops to 1.3 atm, but these parameters can be set up with your own hands.

In the photo and wiring diagram, you can clearly see the device of the pressure switch for the pump.

Pressure switch device for water: wiring diagram

1 - nut for adjusting the lower pressure limit;

2 - a nut of adjustment of a difference of the lower and upper limits of pressure;

3 - terminals for connecting wires from the pump;

4 - terminals for connecting to a single-phase power supply network;

5 - terminals for grounding.

In fact, the water pressure switch for the pump is a relay of a bunch of electrical circuits, which has two contacts, and responds to changes in pressure parameters in the water supply system. The pump pumps water while the contacts in the electrical circuit are closed, but when they open, the power to the pump is turned off and it turns off.

The operation of the contacts in the electric circuit directly depends on the set limits of the on-pressure and the off-pressure of the pump. After a certain period of time, these contacts may oxidize, which will require cleaning.

Setting the water pressure switch for the accumulator and pump

As we noted above, the relay initially has its own factory settings. But we can customize the operation of this mechanism on our own according to the values \u200b\u200bthat are convenient for us. How to do it?

1. In order to increase the lower pressure limit, we need to turn the nut adjusting this limit clockwise (see diagram above) or counterclockwise to decrease this limit.

2. Both of these nuts have a mechanical effect on the pressure control spring in the relay. Using the first, we set the lower limit, and the second - set the necessary difference in pressure limits.

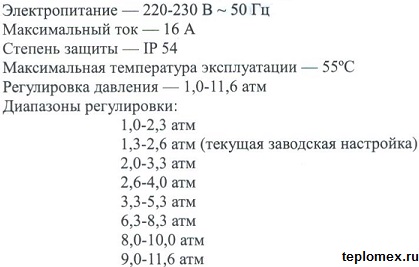

Pressure Switch Specifications

Specifications and Relay Settings

Malfunctions of the pressure switch for the pump and how to solve them

1. The pump does not turn on.

It is necessary to check the presence of water in the suction section of the pipeline and the voltage in the mains. Turn off the power and turn it on again after a while.

2. The pump often turns on and off.

Try lowering the cut-off pressure threshold, perhaps its value is too high.

3. The pump does not turn off.

Check the maximum working pressure of the pump. Normally, it should be higher than the pressure of switching on the relay by 0.8 atmospheres. It is also worth checking the line for leaks and air accumulation in the water supply system.

Today we disassembled the device and the principle of operation water pressure switch for pump, its features, specifications and applications in everyday life. This is a convenient, modern and inexpensive mechanism that allows you to automate the operation of the entire plumbing system of a private house. Watch the video.

Living in a city apartment, we do not know how the plumbing system of an apartment building is arranged. Our task is to open the tap, and water will definitely flow out from it under a certain pressure, sufficient and convenient for use. In private housing construction, everything is different, because you have to learn to understand all communication networks, and in water supply, too. And here you can not do without a pressure switch. So, the topic of this article: RDM 5 pressure switch - adjustment, instruction for use.

Why is the brand of this device chosen? The thing is its high technical and operational characteristics. Judge for yourself:

- It works from a 220-volt network, and this is a great convenience, that is, I inserted the plug into the outlet, and nothing more needs to be done.

- It can be used at temperatures from 0C to + 40C.

- Pressure range (working) from 1.0 atm. up to 4.6.

- At the factory, the relay itself is configured: the lower level is 1.4 atm., The upper is 2.8 atm.

- The pressure drop is 1.0 atm. - This is the minimum indicator.

- Degree of protection 1P 44.

- The internal size of the connected nozzles is ¼ inch. Do-it-yourself installation is not difficult.

Principle of operation

So, the RDM 5 device is a two-contact relay used for switching an electric network. It works only depending on the pressure of the water. Here is his working principle:

- The device is adjusted to the lower and upper limits. If the water pressure in the pumping station of the house is below the upper limit, then the contacts of the relay itself are closed, that is, current flows through its electrical circuit. So, the pump itself is working.

- As soon as the water pressure in the system exceeds the upper limit, the relay is activated to turn off the supply network, that is, its contacts open.

As you can see, the principle of operation of the pressure switch is quite simple. The main thing here is to fine tune the limits.

How to adjust

Often you come across such a position of the installers that, supposedly, the set pressure of the relay at the factory is enough for the water supply system to work comfortably and satisfy the requirements of the owner of the house. But, as life shows, moving to your own private house, where a modern pump station with a pressure switch is installed, the water pressure does not satisfy us (it is small). To ask a specialist to regulate the pressure in the system is useless (most often), so it’s worthwhile to independently understand this issue.

So, the water supply system of a house most often consists of:

- The point of water intake - this may be a village water pipe or a well with a submersible pump.

- Pressure switch with accumulator.

- Water treatment in the form of a system of containers and filters.

- Consumer.

How to correctly adjust the pressure switch. Firstly, it is necessary to understand what pressure will be necessary so that it is sufficient in the process of opening all points of consumption, especially the soul, as the most powerful consumer. Secondly, it is necessary to know the pressure at the point of water intake. After all, how does the relay, and accordingly the pump. If the pressure at the sampling point is below 1.4 atm, then the relay will not even turn on, that is, the pump will not work. This often happens if your private house is connected to the village water supply network, where the pressure most often does not rise above 1.0 atm.

If water is taken from a well or a well using a pump, then the pressure in the home network will depend on the technical parameters of the unit. In any case, not lower than 2.0 atm. That is, you don’t have to worry that the relay will not turn on, so you can safely carry out its adjustment.

How to set the lower pressure limit

First of all, it is necessary to adjust the lower pressure level. Two nuts are installed on the relay housing. The first (it is larger) regulates exactly the lower level, the second difference between the lower limit and the upper. We are interested in the first. With the help of this nut, the state of the fixing spring is changed. When the nut is rotated clockwise, the spring is compressed, thereby increasing the lower limit of the water pressure in the system. When rotating counterclockwise - decrease.

Let's look at an example where there is a need to raise the upper limit, say, to 4.0 atm., And leave the lower limit within the factory limits. To do this, turn the large nut clockwise to the desired value. A nut of a smaller size also rotates clockwise to the rate at which the pump will turn on at a pressure of 1.4 bar.

True, this method, as practice shows, is not the most accurate. Moreover, in the factory settings, most often the spring of the small nut is practically weakened, so that it does not create the necessary pressure difference. Its optimal indicator is 1.0 atm., But actually - 1.3 atm.

Therefore, it is worth adjusting in a different way. For example, to equalize the pressure using a hydraulic accumulator (these are special expansion tanks for the water supply network, they are blue). True, this method is quite complex and lengthy. In principle, it is necessary to select the pressure by the “poke” method. That is, we set up the relay, inserted it near the water supply system, turned on the pump. If the indicators do not match, it is necessary to completely shut off, drain the water from the expansion tank (from its lower part), bleed air from its upper part. And thus adjust the pressure parameters to the necessary. And it can take a lot of time.

Attention! The pressure in the air part of the accumulator must be 10-20% less than the lower limit of the pump station. Such adjustment can be carried out only on the expansion tank, which is disconnected from the water supply.

There is another option, but for this you will have to remove the relay housing and make an adapter, because testing and adjustment will have to be carried out not with water, but with air using a compressor. It is the manometer of the compressor unit that will serve as an accurate reference point for the pressure in the device. At the same time, it is possible to carry out relay settings right on the spot when the compressor is on. It is convenient and fast, and also quite accurate.

And a few more useful tips.

- The pressure switch must only be connected to an earthed outlet.

- The cross-section of the supply electric cable must correspond to the power of the pump unit.

- It would be better if in electrical circuit water supply at home to install in series another pressure switch with slightly larger pressure thresholds. Because at the RDM 5 device contacts are often sticky.

Conclusion on the topic

As you can see, the adjustment (adjustment) of the pressure switch RDM 5 of the pump installation is not the simplest thing, but quite serious. Of course, you can leave all the factory settings, but they may not provide water to the house fully. Therefore, understand the adjustment process and try to carry out this process with your own hands. And let our article be for you, as an instruction for use.

Similar entries: