Pump trickle operation manual. Vibration pump "Trickle": technical characteristics, advantages and disadvantages

Some brands of domestic pumps are known and popular since Soviet times. Even their foreign counterparts, which flooded the market, did not shake their reputation. Such “dinosaurs” include the vibration pump Brook of Belarus production, serving our summer residents faithfully for more than forty years.

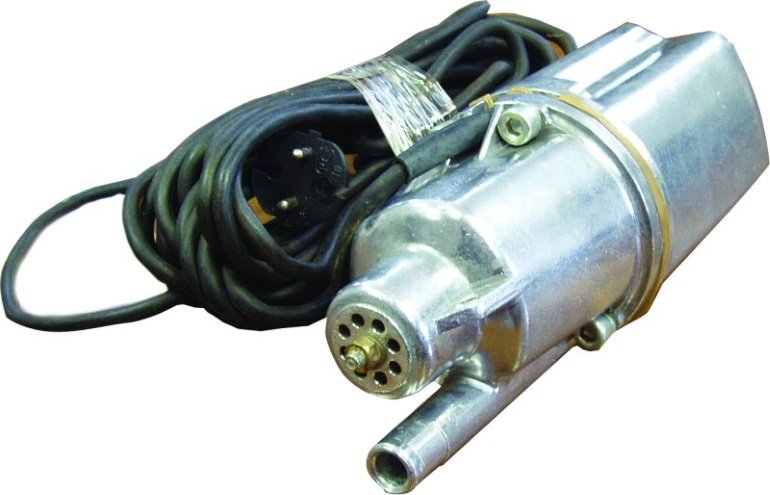

Today it can be found in almost every second country house, where there is a well or a well. What is not surprising: the unit is of good quality, low weight and dimensions, ease of use and affordable price.

Design and parameters

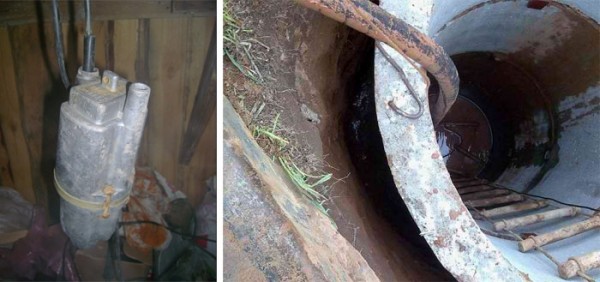

The electric pump Trickle belongs to the units of the vibrational type (see), pumping water due to frequent vibrations of the membrane (or diaphragm), which alternately sucks the liquid into the body and pushes it out.

Principle of action and types

The movement of the membrane is associated with pressure fluctuations inside the device, which in turn decreases and increases as a result of the action of an alternating current that creates a magnetic field.

That is, the “Streamlet” pump does not contain any rotating or screws, as well as bearings subject to friction, therefore it can work for a very long time without breakdowns. It works from a 220 V network, weighs about 4 kg, has an elongated elongated shape, so it can be used both in wells and in wells with a diameter of more than 100 mm.

There are two types of such devices:

- Brook 1 - a pump with an upper water intake. This design allows it not to overheat, since the system is cooled by the pumped liquid. In addition, he does not stir up water, lifting particles of sand and silt from the bottom, and he himself is less likely to clog them.

- Brook 1M - a pump with a bottom water intake. With it, you can completely empty the tanks and pump out water from flooded rooms. To protect against overheating, a temperature sensor is built into it, turning off the unit in case of overloads or lack of water.

Specifications

The main specifications are indicated in the table:

Application area

Vibration pumps such as Trickle are not designed to solve large-scale tasks for the water supply of enterprises or apartment buildings.

These are low-power units for domestic use, with the help of which the following actions are carried out:

- Providing water to a residential building with a small number of residents. For a large family, it is unlikely to be suitable, since it will not be able to simultaneously provide pressure at once in several water outlets, for example, in a shower cabin, kitchen faucet and washing machine. Seven liters per minute is not enough for this.

Note. The instruction does not recommend connecting such a pump to the house and at the same time use it for irrigation or other needs on the site, as this can lead to its overload. Or you should always make sure that it is used alternately.

- Automation of water supply from a sparse source (see). If the water in the well or well arrives very slowly, powerful pump empty it pretty quickly and shut off, or just break, idling. Low-power pumps Trickle in this situation will work stably, pumping out water, albeit slowly, but without interruptions to restore the water level and without agitating the bottom bottom layer.

- Draining basements and cellars, pumping water from pools. This device is useful to have for all summer residents and owners of houses whose underground premises are flooded during spring floods. For their drainage, a vibration pump Trickle 1M with a lower water intake, which can pump out all the water, is best suited. Of course, this will take a lot of time, but still it is better than scooping and carrying water out of buckets.

Tip. To prevent the pump from clogging, it is advisable to equip its suction port with a special filter or place the device in a filter cup.

- Filling the heating system. If the house has already been built, the heating system is installed, and the water has not yet reached the site or has not yet managed to build its own source, the system can also be filled using a low-power pump lowered into a container of water. It is connected by a hose to a drain valve on the radiator, it is opened and the unit is connected to the network. During the injection, it is necessary to control the pressure on the pressure gauge in order to turn off the equipment in time.

- . Wells in the country, visited only in the warm season, are often silted up due to irregular use. A filter clogged with particles of silt starts to pass water worse, its level drops. To solve this problem, a borehole pump will also help, which must be lowered to the bottom and turned on. The vibration he creates will knock out solid particles from the filter. Mixing with water and passing through the pump, they will be removed from the source, cleaning it. And this dirty water can be used to water the garden or fill the storage tank. Pumping is performed until the pressure becomes stronger and the water is cleaner.

An indispensable brook and as a fallback. Such equipment can be bought "in reserve" in case of failure of the main one.

Its price will not breach the family budget, but at the time you choose a new pump or repair an existing one, the house will not remain without water supply. The trickle will provide the minimum needs.

What to do if the pump is broken

Since the design of the device is very reliable and does not contain rotating and abrasive elements, malfunctions of the Trickle pump during the warranty period of 30 months are quite rare. And if they happen, then it is repaired for free.

But nothing lasts forever, and over time, problems can still arise. Most often, they are associated with the ingress of large abrasive particles or water into the mechanism. Why is this happening and how to troubleshoot with your own hands?

- Due to the action of solid particles that have penetrated, despite the integrated filter, the rubber valve may become deformed or break. It can easily be replaced with a repair kit or by cutting a similar part out of thick rubber. For example, from a cork from bottles with liquid medications.

- Water enters the pump as a result of depressurization of the housing when the device is close to the walls of the well or works in the well without a shock-absorbing rubber ring. By vibrating, it receives impacts on the body, which does not withstand such a load. Water poured into it leads to the detachment of the magnet from the fill. To fix it, you need to cut the grooves on the grinder on its surface, fill them with waterproof sealant and insert them back, holding them well to dry.

It is important! During further operation of the pump, it is necessary to exclude its contact with the walls of the casing, as well as work in dry mode.

Conclusion

Having in the country arsenal such a useful device as a low-power vibration pump, you can use it not only to supply water from a local source, but also for many other purposes. According to many characteristics, the Trickle is inferior to modern powerful models, but its stable operation and reliability are a guarantee that you will never be left without water for everyday needs.

You can get additional information about the nuances of its installation, operation and repair from the video in this article.

Despite prolonged use (since Soviet times), the trickle pump is widely popular and available for purchase to every citizen of the country. The submersible device meets the quality and safety standards, which is why it has not yet been abandoned for its use at home. In our article today, we will analyze what an electric water mechanism is with all the ensuing details.

There are a number of nuances that must be considered before installing and operating devices for pumping water from a well or well. As known, submersible pump (it belongs to such varieties) is most often used in summer conditions, so the owner should pay attention to the following characteristics:

Attention! The pump is designed in such a way that in the process of its activity, heat is removed from the internal mechanism. This is achieved thanks to the device of the upper water intake.

What is the device capable of? Is it suitable for home?

The vibration pump is not able to solve global problems associated with regular consumption of water, but it can eliminate minimal problems. It is worth noting that for a large house and the required amount of water for it, such a installation will not cope, since their traditional power reaches an average of 220 watts for cheaper options and 300 watts for more expensive ones.

For country conditions submersible pump It is quite suitable, because there are corresponding technical specifications. Only on condition that you do not use a bathtub, washing machine or sink at the same time. In such cases, only one source of water intake can be included.

Important! Do not connect the submersible pump to multiple volumetric consumers at the same time. This will cause overloading of the pumping system and, accordingly, its breakdown.

The purpose of the "brook"

Most owners in private areas have advanced pumping units, but a submersible vibration pump always has in stock for the following needs:

- as an alternative substitute for failure of the main pumping equipment;

- it is applied to sources from which water is slowly filled;

- a clogged water supply can be reanimated with the help of the traditional Soviet "brook";

- the pump specializes in pumping water out of basements and cellars during the flood season;

- pumps water into a new heating system or supplements the old one, and flushes it.

Thanks to its multifunctional use, the vibration pump can operate stably under all the conditions listed, subject to the operating rules. If you plan to periodically use a small-sized pump, after each use it must be dried and stored in dry conditions. It is not recommended to leave the device for the winter in a well or well.

If you use a vibrating pump for domestic use, then it certainly meets some of the advantages and disadvantages. The device has an affordable cost and low power consumption. Due to the economy, the consumer is eager to buy such a device.

The submersible pump is characterized by ease of use and compactness, which will allow it to be placed even in the most difficult conditions. The casing of the installation is made of anti-corrosion material, while all working parts are placed inside, which reduces the risk of mechanical damage. The pumping device is equipped with good magnetic permeability, and water is pumped using a vibrating membrane.

Among the shortcomings, one can distinguish such technical characteristics: low productivity and inability for a long time in the well in an idle position. If you leave the structure immersed in water for a while, it will acquire an orange tint and silt, which indicates the presence of iron and organic impurities in water.

Repair work and troubleshooting

When operating pumping equipment, you must ensure that it does not come into contact with the walls of the well, as this negatively affects the integrity of the body. Due to the force of vibration, impacts on the walls will be quite powerful and within 1 minute, the trickle will receive 100 hits. As a result of this, cracking of the case occurs, and this entails an early failure of the mechanism. If the device nevertheless suffered from mechanical impact or the valve became unusable, an inspection and repair work should be carried out.

![]()

- To begin with, take the device out of the well and dry it, then disconnect the electrical part from the magnetic.

- We carry out depressurization of the case and, if necessary, replace the working mechanism. If the valve fails, it can be replaced with an ordinary medical plug.

- If pebbles get inside the mechanism, a new working device may be needed. Such an engine can be found in the plumbing market or in repair services.

- The pump must be assembled using a liquid sealant, and only after it has “grasped” can one check its performance.

Note! Troubleshooting a trickle pump is not difficult, but requires some skill, so if you don’t know some of the nuances, you will need to consult a specialist.

Pumps "Streamlet" are very similar to the model "Kid," both in terms of use and characteristics. Both were developed in the USSR 40 years ago, for the needs of summer residents. But so far they are in high demand. The design of the pump is well thought out, there are enough possibilities to meet the needs of a small family and water the site up to 12 hundred parts. The pump rarely breaks, its service life is 8 years.

Technical characteristics of the trickle pump

Energy consumption does not exceed 300 watts, which is comparable to an aquarium filter pump for 500 liters. If it is very necessary, it can be started from the battery. At a depth of 40 m, productivity is 40 liters per hour, but with a surface fence (not more than 1.5 m) - 1500 liters per hour. The operating mode is 12 hours a day, the pump transfers normally. This is due to the design features, excess heat is removed using pumped water.

The scope of the pump is extensive - pumping water from wells, wells, ponds, pools, reservoirs and natural reservoirs.

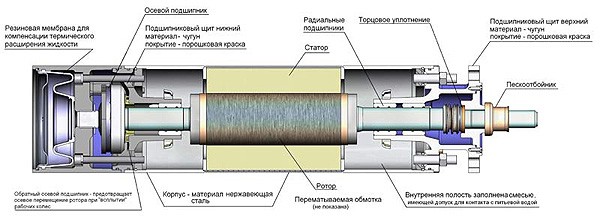

Pump device

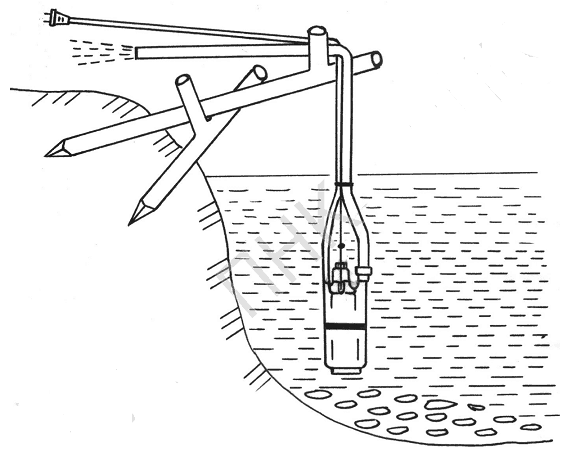

When installing a "brook" mounts are optional, in most cases it is enough to hang them vertically on a cable. But categorically you can not hang the pump over the wire. During operation, vibration occurs, which will damage the wire. The body is made of metal and is well protected from damage, but for additional cushioning from above. put on a rubber ring. All components of the device are easily replaceable.

Principle of operation

The magnetic field created by electromagnetic voltage leads to a change in pressure and due to the fluctuation of the diaphragm, water is raised. Long non-stop operation is possible due to the absence of breaking parts.

The magnetic field created by electromagnetic voltage leads to a change in pressure and due to the fluctuation of the diaphragm, water is raised. Long non-stop operation is possible due to the absence of breaking parts.

Application possibilities

Scope "Brook" is purely household. For industrial use, he has enough power, the same applies to farms. If you have a large flow of water, it is better to purchase a powerful pumping station. A 100 cubic meter trickle pool will fill up in a week. Its main convenience is the possibility of use in shallow wells. Where a powerful pump will empty it very quickly and turn off, the trickle will work and pump up to 6 liters per minute. Often, you can observe increased well capacity by 30% after using the device.

Scope of application:

- Delivery of water from wells, boreholes.

- Water delivery for irrigation system.

- Pumping water from reservoirs, pools.

- Filling the heating system.

A trickle is used to clean wells, due to vibration and liquid suction this happens quickly.

Drainage pumping

The pump was designed for pumping drinking water. But the situations are different and the "Stream" was used as drainage. There are special protective nozzles for working in dirty water. When using the device for other purposes, its service life is significantly reduced. And getting into the mechanism of small stones and sand is guaranteed to disable it. Do not use to pump viscous liquids.

The designers laid down enough power to quietly pump out the meltwater of moderate pollution. But before such work, install an additional protective filter, it resembles a glass.

There are a large number of modifications of protective covers, but the most common is a rubber cover, which is put on a heated pump.

Design features

The design of the pump is very simple and consists of the following elements:

And there are only two components:

- Vibrator or mechanical. Which includes the stem, anchor and shock absorber. The anchor is made of electrical steel and filled with a steel rod. After the anchor, a shock absorber is put on and fixed with M12 nuts. Next, there is an aluminum coupling on which the rubber diaphragm is mounted, which is needed to separate the electrical and internal parts of the pump. On the upper part there is a rubber non-return valve, which protects the suction part of the pump from water ingress, with increasing pressure.

- Electric. It contains an electromagnet, which is made of a U-shaped wire, and coils with a copper wire 0.6 - 0.7 mm in diameter are worn on it.

The core together with the coils are placed in an aluminum case and fastened with epoxy resin. Filling acts as a reliable means of fixing parts, and also effectively removes heat.

"Brook" connection sequence

At the very beginning, a check valve is attached to the pipe. This will save you the need to control well completion. The nozzle will prevent water from draining when the pump is turned off. A bowl-shaped filter is attached to the suction pipe. This will protect the working chamber from flooding.

At the very beginning, a check valve is attached to the pipe. This will save you the need to control well completion. The nozzle will prevent water from draining when the pump is turned off. A bowl-shaped filter is attached to the suction pipe. This will protect the working chamber from flooding.

Discharge hose Attaches to the check valve. Water flows through the hose to the outlet tap. The second end of the hose is attached to the accumulator. For a more secure fit, attach them to the adapter.

The electrical cable and discharge hose are secured together with polymer clips or cable ties. Using wire will damage the hose. In the hole located in the upper part of the body, a polymer rope is attached, on which the pump will hang in the well.

After everything is assembled, he slowly and carefully lowers into the well. The entire weight of the device is held by a rope. Do not use the hose to lower it.

Repair Features

Due to the low cost of the "Brook", many neglect the repair, and immediately buy a new device. Repair is simple, but the cost is low. Therefore, do not discard a broken pump, but have it repaired and buy a new one. So you will have 2 devices, which will provide you with an uninterrupted supply of water. If you have free time, then you can do the repair yourself, the design is very simple.

Pump disassembly

The first thing you need to do is remove the mounting bolts. They are covered with rust and tightly sit in the body. If it did not work out, use a screwdriver to cut off the heads with a grinder. Use a small diameter disc to prevent accidental damage to the motor. Remember to secure the pump in a vise.

Membrane replacement

A common cause of pump failures is their membrane failure due to the ingress of a foreign element. Special repair kits are on sale. If there are no spare valves and membranes on hand, they will be replaced with rubber caps from medical preparations. Such a makeshift solution does its job well.

A common cause of pump failures is their membrane failure due to the ingress of a foreign element. Special repair kits are on sale. If there are no spare valves and membranes on hand, they will be replaced with rubber caps from medical preparations. Such a makeshift solution does its job well.

Winding replacement

Here you can not do without special engineering knowledge, the best option is to give it to a specialist for repair.

Electromagnet surface repair

Such damage is easily repaired by a car sealant. Using a grinder, apply shallow grooves, and then apply glue.

The price of the pump "Brook"

The price of the pump depends not only on the technical characteristics, but also on the country of the manufacturer:

- Power 225 W, capable of lifting water from 60 m - 2500 r.

- Power 280 W, capable of lifting water from 40 m -1600 p.

It’s better to buy a more powerful model, the price difference is not very big, but according to the characteristics, the gain is obvious.

Pros and Cons of "Brook"

Pros:

- Reliability of a design checked for years.

- Simplicity, allowing you to carry out simple repairs yourself.

- Unpretentiousness to working conditions.

- No need for additional mounts.

- Low price.

Minuses:

- Low power.

- The temperature controller is delayed.

- Put the washing machine in one place, and the shower in another, did not work.

When using a pump with a well, it is necessary to use depreciation, which will not allow the walls of the casing and the well to touch. If this is not done, then the pump is guaranteed to fail. The trickle is vibrating and without shock absorption it hits the well.

Although more than 40 years have passed, until now the design has not undergone significant changes, and the quality has remained high. To this pump, in terms of the ratio of technical characteristics, price and service life, there are no equal so far.

Household vibration pumps appeared on sale in the 50s of the last century. Over time, their range expanded significantly, pumping equipment from foreign manufacturers was added, but all the needs of the consumer market have still not been filled. And all because far from all vibration pumps are equally popular. Among the equipment that has not been on store shelves for a long time is the Belarusian-made Rucheek pump. This has been made possible thanks to the many positive properties and stable quality of this unit.

There are two types of pumps - vibration and submersible. Further about the features of each species.

Electricity passing through the system of the unit creates pressure drops, which in turn creates diaphragm oscillations - this is the principle on which the operation of vibration pumps is based.

What is very important - there are no rotating elements in the design of the unit, therefore, no part is subject to abrasion or wear. In addition, since there is no friction, there are no products that appear as a result of this process (for example, dust from metal), so the mechanism is not contaminated. This, in turn, extends its service life.

The water intake hole is located in the upper part of the housing, due to which the vibrating type device not only does not overheat, but also does not suck silt and debris from the bottom of the well.

Vibration models can be used for a variety of household purposes.

All About Submersible Models

Submersible models differ from vibration ones in that they are designed to work in depth. But they can be used only in cases where the water in the well is clean and not saturated with salts. Therefore aggregates submersible type cannot be used for work in tanks with dirty water or in open water.

Submersible models differ from vibration ones in that they are designed to work in depth. But they can be used only in cases where the water in the well is clean and not saturated with salts. Therefore aggregates submersible type cannot be used for work in tanks with dirty water or in open water.

Submersible products can work 10-12 hours a day, but do not be too zealous - the mechanism must be periodically turned off. This and its service life will extend and increase productivity.

Submersible models weigh 4 kg and can pump out about 450 liters of fluid in one hour. Parts are inexpensive and easily replaceable, therefore, in case of breakage, it is possible to repair the product at low cost.

The metal case is durable and airtight. Moreover, it is so high-quality that there are practically no cases of depressurization.

To prevent equipment from touching the well walls, a safety ring made of rubber material is integrated. To fix the unit, you do not need to fasten it to the walls of the well, but you just need to attach it to a cable or twine, so installing the device is quite simple.

Also on the submersible unit there is a mounted sensor. It determines when the Trickle pump overheats and automatically turns it off.

Specifications

Each modification has its own technical characteristics. But there are common characteristics inherent in all models. These include:

- Power consumption. Each device requires 220 to 300 watts to operate.

- In order for the Rucheyk pump to run smoothly, it needs a voltage of 220 V. In other words, it needs a regular household electrical network.

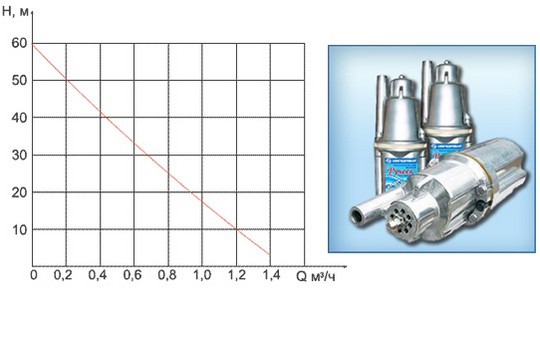

- The maximum pressure indicator, depending on the model, is from 40 to 60 m.

- Performance depends on depth. For example, if the fluid needs to be raised to a height of 1 m, then the pump can deliver 1.5 cubic meters of water per hour. From a depth of 40 m during the same time, the device pumps about 430 liters of fluid.

Based on the specifications listed above, the Streamlet pump is an ideal unit to meet the needs of any country house.

The following are also the technical specifications of the vibrating equipment:

- Two working chambers are located in the pump casing. One of them is motor, the other is a pump room with an anchor and a pump.

- The cameras are separated by a round diaphragm, for the manufacture of which thick elastic rubber is used. An anchor is attached to the stem, which is equipped with a rubber shock absorber.

- A magnetic coil is located in the chamber with the engine. It causes oscillations of the armature, which drives the pumping fluid pump.

- To ensure water drainage, the pumps have a valve. When the unit is turned on, it closes the hole, and when the device turns off, the valve moves back and the fluid without obstacles leaves the working area of \u200b\u200bthe pump compartment.

Advantages disadvantages

The most important indicator is the stable quality of the pumping equipment of this brand, good performance, efficiency. In addition, domestic products differ in the following advantages:

- Simple and reliable design.

- Relative unpretentiousness in work.

- Reliability, low cost.

- High maintainability - it is possible to replace all rubber components and elements.

- Simplicity of operation.

- It does not require expensive maintenance.

- It can be used for pumping water from any artificial or natural reservoir, tank, well, well.

- The electrical part of the vibration pumps is perfectly cooled in cold water. Since the pump is located in the upper layers of water, it cannot become clogged with debris or sludge, which usually accumulate at the bottom.

- The pump kit includes a thermal protection device, therefore, if the unit heats up to critical values, it automatically turns off. This usually happens if the water level in the source drops significantly.

There are also disadvantages in devices of this brand. It:

- Insufficient productivity, so the Rucheyk pump is designed for operation in wells and wells with a low water level - it can supply water for a long time, and at the same time it will not drain the hydraulic structure. Because of this, the disadvantage as such can not be considered.

- The thermoregulation sensor may not always work. This leads to overheating of the unit, which reduces its service life.

- Vibration models can destroy a well.

- Submersible pumps must not be used to pump contaminated liquids and fecal effluents.

Scope of application

Aggregates of the brand "Trickle" are not intended to fill production needs, but they can very well fulfill the tasks in a small suburban building, whether it be a house or a summer house. They are used for:

- Watering the garden and the garden.

- Filling heating systems to put them into operation.

- Pumping liquid from tanks, cellars, pools and other tanks.

- Water supply of a residential building.

Interesting! It is only possible to provide a residential building with water if one water distribution point is used at the same time. For example - a washing machine, shower, washbasin.

Pumps are also used to restore well operation. For this, vibration models are used. The vibrations that the device creates during operation affects the well filter by high-frequency waves. Due to this, silt and sand is washed out of the mesh structure. Only 3-5 hours of operation of the pumping device will help restore the water flow by 35-40%.

Repair Features

Many consumers do not repair pumping equipment, but prefer to purchase new products, because they believe that reanimating the device is expensive and difficult.

But in fact, just the opposite: pumping units have a very simple design.

Interesting! Parts for replacing failed elements are more than affordable, so repairing equipment will be far from expensive.

But, if you do not know some features, the repair may not succeed at all. Problems may occur with:

- Dismantling the mounting bolts. During the operation of the pump, the fasteners become rusty and cannot be unscrewed. The best way out is to cut off the bolt heads with a grinder. If you take a large disk on a grinder, you can damage the internal mechanisms, so a small disk element is needed.

- If the filling of the electromagnet is damaged, it is necessary to eliminate this malfunction with car sealant. It is easy to do. On an electromagnet grinder, make shallow grooves - they will help to reliably strengthen it. Then it remains only to apply the adhesive composition to the magnet itself.

- If the membrane is worn or damaged by foreign objects, it must be replaced with a new one.

Important! If the winding is broken, if there is no proper knowledge, it is best to consult a specialist.

Even with the appearance on our market of well-known imported water pumps, the products of the Belarusian company Livhydromash did not lose their popularity. The pump Rucheyek whose characteristics are optimal for water supply of a small house and watering the site, we are loved by summer residents for reliability and low cost.

Unit Features

All pumps of the Brook lineup are domestic. They are not intended for pumping large volumes of water and are used only in individual wells and wells with a diameter of more than 100 mm and a depth of not more than 40 m.

At the same time, their capacity is quite enough to provide for domestic needs and watering of garden plantings on a personal plot (see).

Device and principle of operation

Structurally, all models practically do not differ from each other: they are all submersible, vibrational type (see).

The main elements of the pump are located in the housing:

- Electromagnetconsisting of a core and two coils;

- Anchor;

- A piston rigidly connected to the anchor, which during movement pushes fluid from the chamber into the outlet pipe.

The only distinguishing structural characteristic of the Brook pumps is the location of the water inlet. On all models except Trickle-1M, it is located in the upper part of the case.

Such an arrangement reduces the likelihood of solid impurities entering the aggregate - sand and silt in the water. It also eliminates overheating of the engine, which is located in the lower part and is always cooled by the pumped water.

For reference. Pumps with a lower intake can be used to drain various containers and tanks.

Terms of Use

In order for the device to work for a long time and reliably, the instruction manual for the pump Trickle must be strictly observed. As well as the rules for its installation.

They are as follows:

- In a well or well, the device is lowered vertically with a cable threaded into special eyes on the body;

Note! Do not lower or suspend the pump on the power cable. It will be damaged quickly due to vibration.

- So that the unit does not come into contact with the walls of the well during operation or, a protective rubber ring must be put on it. As a rule, it comes complete with a pump;

- Before mounting to the source, the supply cable must be fixed on the supply pipe so that it does not sag. It is easy to do it yourself with the help of plastic clamps.

During operation, after every two hours of continuous operation, the device should be turned off for 15 minutes. In general, it is designed for 12 hours of work per day, therefore, with round-the-clock water demand, it is advisable to have two pumps or equip the system with a storage tank (hydraulic accumulator).

Equipment

Each pump of any model, in addition to its own, includes hose clamps, a rubber shock absorber and a cleaning filter. The length of the power cable depends on the recommended immersion depth of a particular model. It can be 6, 10, 16, 25, 32 or 40 meters.

The price of accessories is included in the price of the device. But all the other necessary elements of the system (check valve, hose, accumulator) are purchased separately.

In addition, a sensor is mounted in the pump itself, which automatically turns it off when overheating, which can occur during prolonged operation or a decrease in the water level in the source.

Specifications

Various modifications of pumps of this brand differ only in power and performance. The table shows the technical specifications for the pump Trickle.

As you can see, the scatter of some indicators is large enough, which requires an explanation:

- Pump performance depends on how deep it pumps water. When diving to a depth of 40 m, it will be about 400 l / h, from a 20-meter depth, productivity will increase to 900 l / h, and if the fence is carried out superficially, from an open source with immersion up to 1.5 meters, it will increase to one and a half cubic meters.

- Another important characteristic about the pump Trickle is pressure. 40m is the nominal head at which the device provides the indicated performance. With increasing pressure to the maximum value (60m), it falls.

- Low power consumption, not exceeding 300 watts and comparable to the power consumed by a conventional computer, makes the device very economical and most suitable for working in sources with a small flow rate. More powerful units will quickly empty it and turn off, shutting off the water supply. A trickle will work evenly, providing even a small (5-7 liters per minute), but continuous flow.

- Such pumps are intended only for pumping clean water with temperatures up to +35 degrees Celsius and the content of undissolved mechanical impurities of not more than 100 grams per cubic meter.

Conclusion

If you believe the reviews of those who have been using Ruchek pumps at their dachas for a long time, the productivity of the sources - the wells and wells in which they are installed, increases over time. That is, he gradually “swings” them, increasing the flow rate.

Whether this is so in reality or there are other reasons for such positive changes is not exactly known. But in any case, Belarusian pumps deserve good reviews. See for yourself by watching the video in this article.